WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

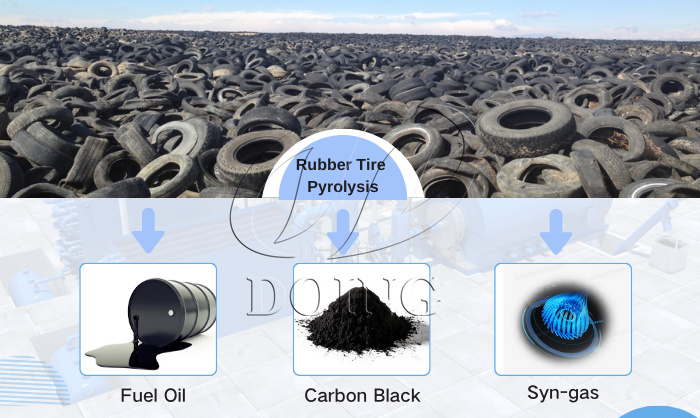

Imagine discovering an oil field that produces 110,000 barrels of refined diesel oil per year simply by recycling waste tires. This oil field requires no exploration, no wellhead drilling, and replenishes itself each year with even more oil than you initially started with. What if you could earn money by processing the oil field and simultaneously keeping the oil? Moreover, what if you were also contributing to pollution prevention and generating carbon credits at the same time? This is not science fiction; it's a thrilling reality, and we are excited to be part of the future of converting waste tires into oil(TDF: tire derived fuel).

Waste tire to oil and carbon black pyrolysis and process

Waste tire to oil and carbon black pyrolysis and process

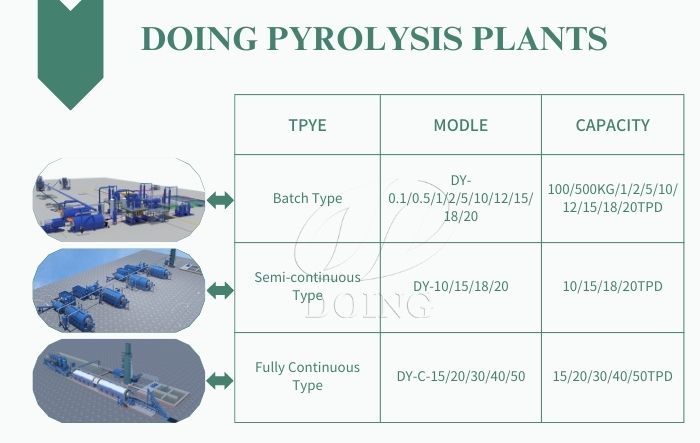

Henan Doing Group manufactures and offers the leading eco-friendly and cost-effective pyrolysis machine for turning waste tires into oil, featuring world-class design and technology. Doing Group has continuously strived to develop the tire pyrolysis machine, conducting extensive research and experiments. Currently, Doing Group has designed different capacities and different configurations of waste tire pyrolysis machine with reduced costs and increased fuel oil output, from 100kg to 50TPD per set, including skid-mounted/batch/fully continuous waste tire pyrolysis machines.

Capacities of batch continuous waste tire oil pyrolysis machines

Capacities of batch continuous waste tire oil pyrolysis machines

A tire pyrolysis facility processing 100 tonnes of waste tires per day yields the following annually:

One 20-pound tire produces 0.875 US gallons of oil.

A 100 TPD (Tons Per Day) tire pyrolysis plant produces 110,000 barrels of oil per year.

A 100 TPD tire pyrolysis plant generates 300 barrels of oil daily.

This commercially proven solution produces over 15 times more oil than the average US oil well!

Waste tire pyrolysis machine utilizes methods like thermal desorption to convert waste rubber tires into oil, carbon black, and steel wire. This process ensures that nearly all components of waste tires are recovered.

Here is the 3D working video of how DOING waste tire pyrolysis machines turn waste tires into fuel oil:

As we can see from the video, the working flow of turning waste tires into fuel oil includes the following steps:

(1) Tire Feeding: input waste tires into pyrolysis reactor manually or by auto-feeder.

Note: If you want to engage in big scale fully continuous tire to fuel oil processing line, waste tires need to be shredded into rubber powder, facilitating automatic feeding and pyrolysis processing.

(2)Pyrolysis tire into oil gas: keep heating pyrolysis reactor at high temperatures, typically between 280-350°C, then there will be thermal decomposition and oil gas production.

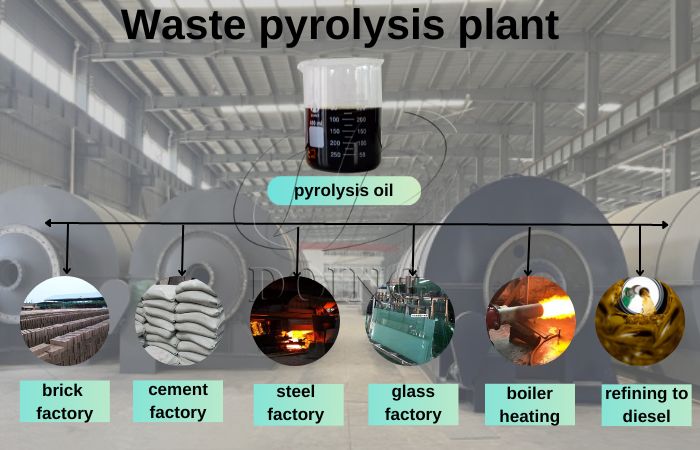

(3)Tyre oil condensation: tire oil gas will be condensed into liquid tire derived fuel through the multiple-stage cooling system. The fuel oil obtained from waste tire pyrolysis machine finds diverse applications by virtue of its high calorific value. It can be used directly as substitute conventional fuels in various industrial heating applications such as boilers, furnaces, cement/brick/steel/glass making factories, and power plants, etc.

Waste tire pyrolysis derived fuel applications

Waste tire pyrolysis derived fuel applications

(4)Exhaust gas purification: exhaust gas will be purified by environmental protection device of waste tire pyrolysis machine. The syn-gas can be treated and is emitted when achieving environmental standards.

(5)Residue collection: Residual solids like carbon black will be recovered from pyrolysis reactor by carbon black transfer system and then be collected.

(6) Pyrolysis oil Distillation: if have higher requirements of the tire derived fuel extracted from tire pyrolysis machine, tire pyrolysis oil can undergo further distillation optimizing its usability and value, such as be used in heavy machinery, diesel generator or vehicles like trucks, tractors, ships, boats, etc.

The tire to fuel oil recycling industry is poised for significant growth as countries prioritize sustainable waste management practices and seek alternatives to fossil fuels. So what exactly are the benefits of converting waste tires into oil? Let us analyze the current situation of tire recycling in the United States.

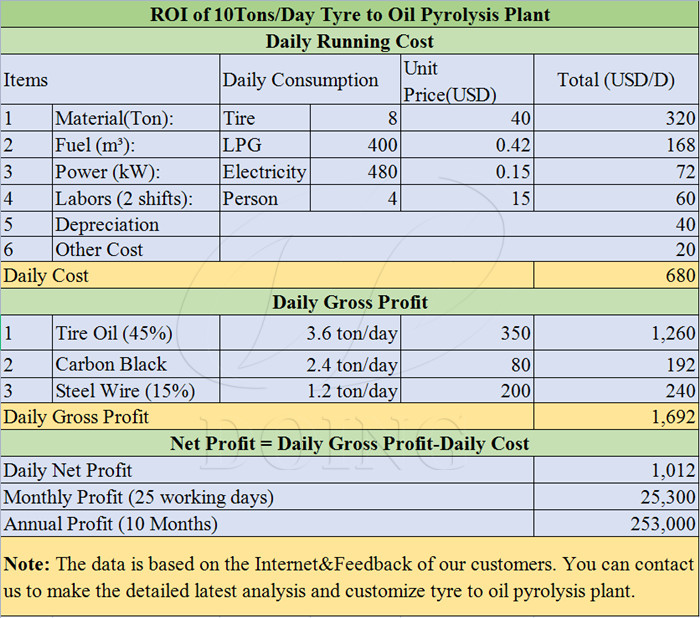

Profit analysis of tunring waste tire to oil pyrolysis machine

Profit analysis of tunring waste tire to oil pyrolysis machine

The United States generates over 350 million waste tires annually. If all these tires were processed by our pyrolysis machine, approximately 7 million barrels of tire pyrolysis oil could be produced yearly. The Oxford tire dump in Westley, California, is a typical US tire dump containing over 14 million tires. A 100-ton-per-day industrial plant could process these tires within six years and yield over 600,000 barrels of oil.

According to the US Energy Information Administration,the average cost of drilling for oil domestically in the US was $1.4 million per hole, excluding exploration, rights, and other expenses. In contrast, a waste tire pyrolysis machine can source and produce oil without requiring exploration or drilling.

The oil is delivered to our facility, and we are paid for processing it. As long as vehicles continue to traverse our roads, our oil sourcerenews itself annually. In fact, our tire pyrolysis oil source is expected to expand as global tire consumption is projected to increase from 1.5 billion to 3 billion.

DOING waste tire oil pyrolysis machine projects

DOING waste tire oil pyrolysis machine projects

Henan Doing Environmental Protection Technology Co., Ltd. specializes in pyrolysis machines that convert waste tires into energy, creating a cleaner fuel, energy, or carbon alternative to crude oil. It represents the purest form of recycling. As a world-leading waste tire pyrolysis machine manufacturer and supplier, we are glad to customize suitable solutions to turn waste tires into oil for all the new and regular customers.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.