WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Waste plastic recycled into oil

Waste plastic recycled into oil

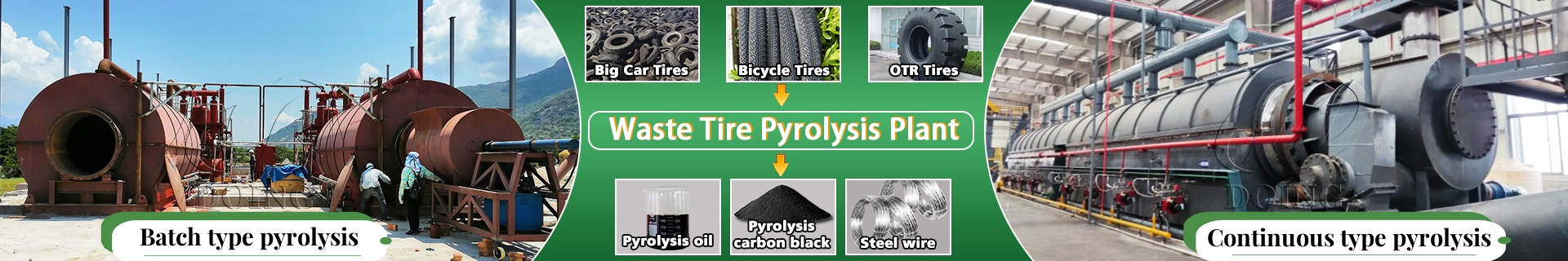

Waste plastics are indispensable materials in the modern world and the application in the industrial field and daily life are continually extensive. Nowadays, there is growing interest in pyrolysis as a technology to convert plastic to oil.

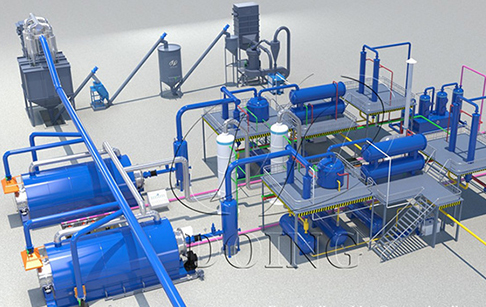

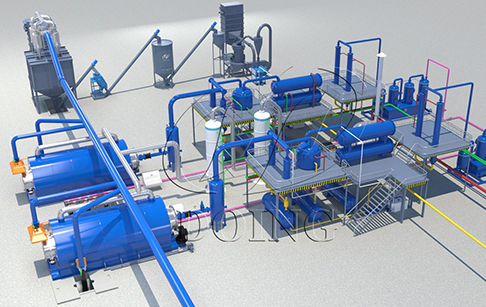

Automatic convert waste plastic to oil machine

Automatic convert waste plastic to oil machine

The automatic convert waste plastic to oil machine is designed with new green technology to convert the waste plastics to the useful fuel oil. Not only the oil produced by the automatic convert waste plastic to oil machine can be used as the industrial and civil gasoline, diesel and even the fuel oil, but also the automatic convert waste plastic to oil machine can solve the environmental pollution caused by plastic accumulation or burning.

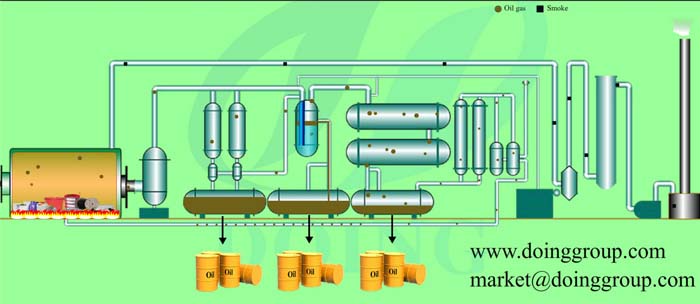

To turn plastic into oil, firstly, the waste plastic should be directly put into the high temperature and high pressure pyrolysis reactor. Then the automatic convert waste plastic to oil machine adopts the indirect heating method to produce oil mixture in the absence of oxygen, which is also called thermal and catalytic degradation processes.

Automatic convert waste plastic to oil machine working process

Automatic convert waste plastic to oil machine working process

Through the condenser, the oil steam can condense into the fuel oil. In the end, in order to produce the qualified fuel oil, the necessary steps are precipitation, filtration, chemical treatment and additives. The plastic to oil process is environmental friendly, energy-saving and safe.

In addition, the automatic convert waste plastic to oil machine is widely accepted by the majority of customers, because of its environment friendly performance. Firstly, the waste air is sealed in the water and can be fully burned, which not only can eliminate the waste gas pollution, but also can save a lot of energy. Second, in the process of production, the waste residue can not be avoided, but the waste solid can be returned to the stove again and used as fuel. What's more, the automatic convert waste plastic to oil machine is equipped with water dust scrubber/pulse dust collector, tail gas cleaning system and other environmental protection system. So there is no pollution to air, water and earth in the whole production process.

Automatic convert waste plastic to oil machine

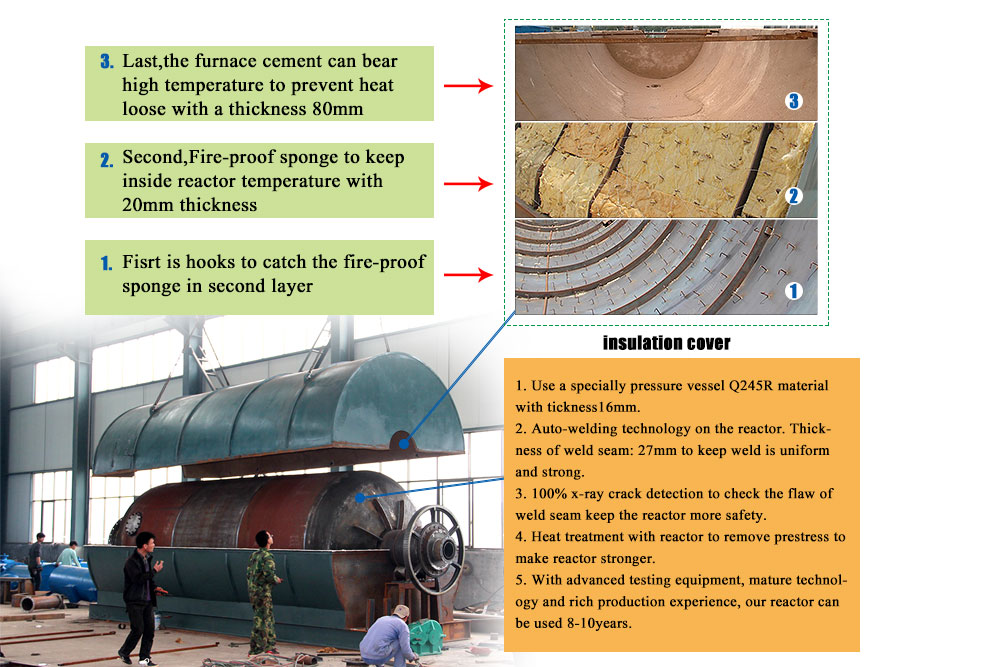

The two keys of convert waste plastic to oil machine are reactor and cooling system.

DOING pyrolysis plant features

DOING pyrolysis plant features

Reactor directly decides the machine's safety and service life. DOING convert waste plastic to oil machine is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

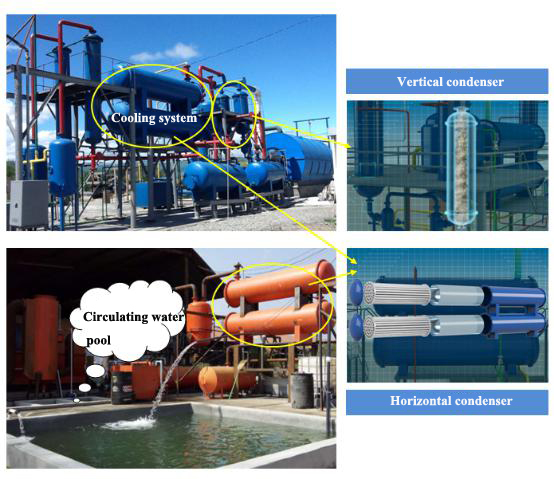

DOING cooling system design

DOING cooling system design

The cooling systems decides oil output of convert waste plastic to oil machine. There are two steps for cooling. Cooling pipe is the first step. The second is condenser. Its inner have 61 pipes in one condenser. The total cooling area is 100㎡. This will guarantee you a high oil yield. The reasonable design has a direct relationship with the oil output.

| Technical parameter of automatic convert waste plastic to oil machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about automatic convert waste plastic to oil machine | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

Automatic convert waste plastic to oil machine aims to turn waste plastic into high quality fuel oil and carbon black while avoiding any pollution. The process design is reasonable, and the equipment is not only trustworthy but also can bring good environmental, social and economic benefit.

1. The automatic convert waste plastic to oil machine is widely used by recycling center, waste plastic recycling company, and Eco-protect Company.

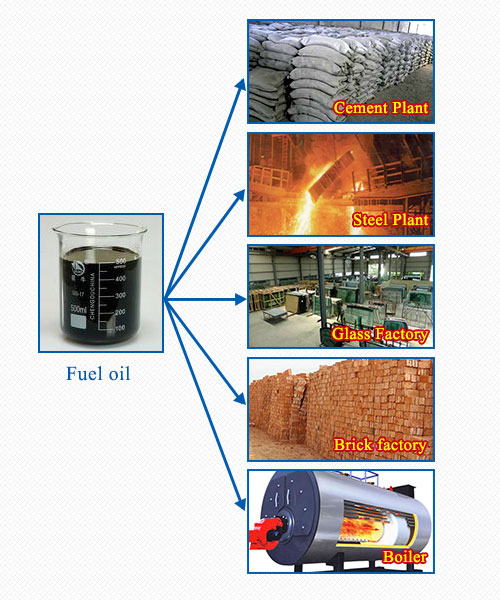

2. The final product from automatic convert waste plastic to oil machine is fuel oil, diesel, carbon black and steel wire. Fuel oil can be used as fuel to heating, such as heavy industries, cement factory, steel milling factory, glass making factory, boiler factory etc. And it can be used for tractors, trucks, and diesel oil generators, if refined into diesel oil by waste oil to diesel plant, which can separate the oil mixture according to the different boiling point of the different composition in the oil mixture. Carbon black can be sold to cement factory, also can pellet them to heating the machine.

Fuel oil application

Fuel oil application

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Skid-mounted waste tire plastic pyrolysis plant for sale

Skid-mounted waste tire plastic pyrolysis plant for sale

Waste Tyre Pyrolysis Machine Technical Parameters

Waste Tyre Pyrolysis Machine Technical Parameters

Waste tire to oil pyrolysis plant

Waste tire to oil pyrolysis plant

DOING Continuous Waste Plastic To Oil Machine

DOING Continuous Waste Plastic To Oil Machine

Oil sludge pyrolysis plant

Oil sludge pyrolysis plant

Small scale waste tyre pyrolysis equipment

Small scale waste tyre pyrolysis equipment

New design pyrolysis plant convert waste plastic to fuel oil

New design pyrolysis plant convert waste plastic to fuel oil

Waste tyre oil extraction and pyrolysis plant for sale

Waste tyre oil extraction and pyrolysis plant for sale

Waste tire recycling plant

Waste tire recycling plant

12T pyrolysis plant recycling waste tires to fuel oil

12T pyrolysis plant recycling waste tires to fuel oil