WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Converting commercial plastic to oil recycling plant

Converting commercial plastic to oil recycling plant

The advantages of converting commercial plastic to oil recycling plant

1.Fast

The unique fast heating system is especially designed for shorten working time.

In market, mostly are horizontal reactor or old design for plastic to diesel distillation machine which take about 3-5days to finish one batch.

2.Easy slagging

Vertical reactor make slagging from bottom automatically and fast.

3.Energy saving

Fast heating system keep temperature even after slagging and you can use for next batch so is energy saving.

4.Safe

Strict quality control system and professional safety devices guarantee our plastic to diesel distillation machine running safely and win a good reputation from customers.

5.Environmental friendly

Professional dedusting systems ensure our plastic to diesel distillation machine runs zero pollution.

| Technical parameter of converting commercial plastic to oil recycling plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

The applications of final products

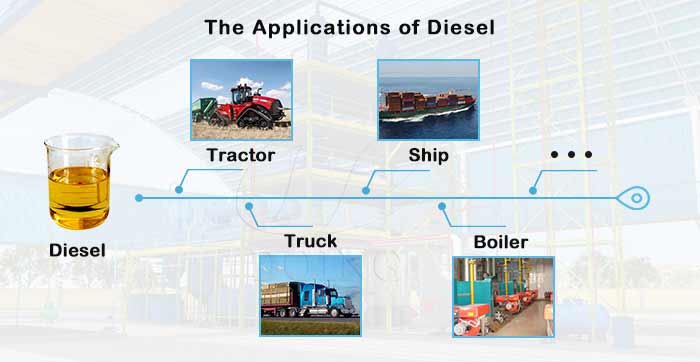

With the converting commercial plastic to oil recycling plant, waste oil can be refined into diesel and asphalt, both of which can be used in different fields for different purposes.

1.Diesel

The diesel obtained from the converting commercial plastic to oil recycling plant can be directly used in heavy duty diesel engines, such as tractors, trucks, ships, boilers, etc. Of course, it can also be used as fuel.

The applications of diesel

The applications of diesel

2.Asphalt

The asphalt obtained from converting commercial plastic to oil recycling plant can be used to pave roads or make other construction materials.

Henan Doing is a professional manufacturer and supplier of converting commercial plastic to oil recycling plant, we can provide turnkey service including sales, installation, commissioning and after-sales, to satisfy you in all aspects. If you are interested in our machines, please contact us to get the latest quotation.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Engine oil purification machine

Engine oil purification machine

Advanced Waste Oil Distillation Plant for Sale

Advanced Waste Oil Distillation Plant for Sale

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Plastic to diesel process plant

Plastic to diesel process plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Used lube oil refining plant for sale

Used lube oil refining plant for sale

Diesel oil made from crude oil working process

Diesel oil made from crude oil working process

Waste plastic to diesel process machine

Waste plastic to diesel process machine

Plastic to diesel converter plant

Plastic to diesel converter plant

Waste plastic to diesel and gasoline plant

Waste plastic to diesel and gasoline plant