WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

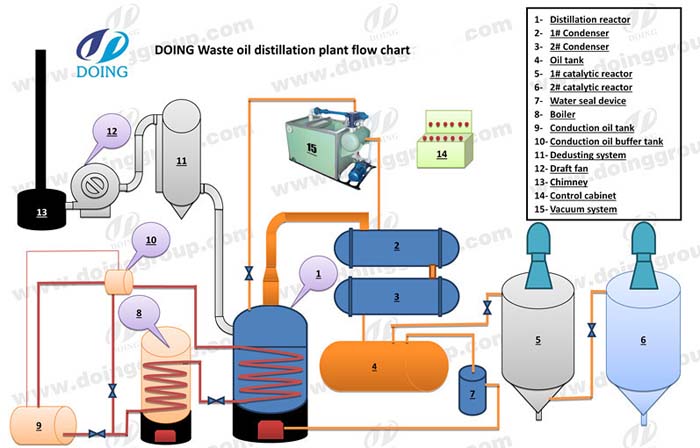

| Technical parameter of used motor oil to diesel fuel processor plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

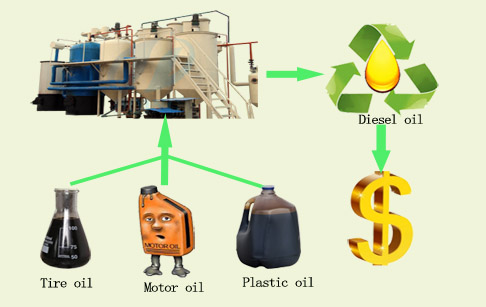

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Engine oil purification machine

Engine oil purification machine

Advanced Waste Oil Distillation Plant for Sale

Advanced Waste Oil Distillation Plant for Sale

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Plastic to diesel process plant

Plastic to diesel process plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Used lube oil refining plant for sale

Used lube oil refining plant for sale

Diesel oil made from crude oil working process

Diesel oil made from crude oil working process

Waste plastic to diesel process machine

Waste plastic to diesel process machine

Plastic to diesel converter plant

Plastic to diesel converter plant

Waste plastic to diesel and gasoline plant

Waste plastic to diesel and gasoline plant