Features

Waste plastic

Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products. Since plastic is non-biodegradable, recycling it is a part of global efforts to reduce plastic in the waste stream, especially the approximately eight million metric tonnes of waste plastic that enter the Earth's ocean every year. Continuous waste plastic pyrolysis plant helps to reduce the high rates of plastic pollution.

Continuous waste plastic pyrolysis plant

The continuous waste plastic pyrolysis plant from Henan Doing Mechanical Equipment Co.,Ltd is a green technology for waste plastic recycling. The continuous waste plastic pyrolysis plant is well received by our customers home and abroad. Till now, our continuous waste plastic pyrolysis plant has been exported to more than 30 countries, such as Italy, Macedonia, Egypt, Jordan, Nigeria, Malaysia, Thailand, Mexico, Haiti, etc.

Continuous waste plastic pyrolysis plant can change waste plastics into fuel oil environmentally friendly. Thus greatly help to solve the waste plastic disposal problem.

Our continuous waste plastic pyrolysis plant has the following features.

Continuous waste plastic pyrolysis plant

1.High oil yield

New technology continuous waste plastic pyrolysis plant has perfect cooling system which is improved based on the old technology. It can ensure all the oil gas get cooled and converted into fuel oil.

2.Environmental friendly

Professional dedusting system will effectively process possible pollution in the smoke thus avoid zero pollution to the air.

Exhaust gas recycling system can recycle waste gas for heating machine directly, which can save energy and environmental friendly during the process of continuous waste plastic pyrolysis plant

3.Safe

We have strict quality control system on each step production of our continuous waste plastic pyrolysis plant which will guarantee machine life and safety.

Technical Data

Continuous waste plastic pyrolysis plant technical data

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

Output |

Fuel oil, carbon black |

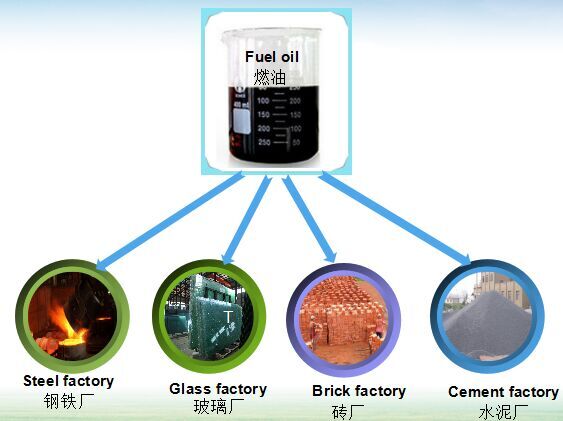

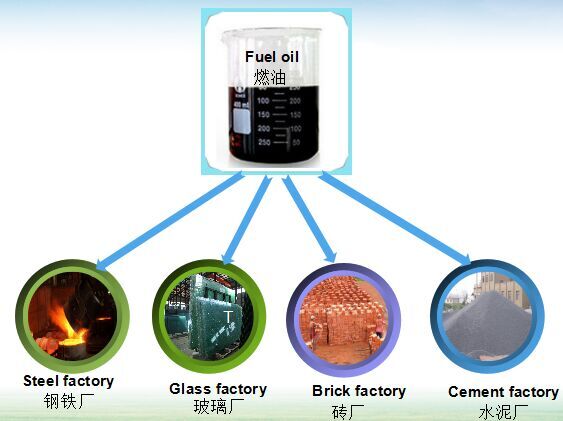

Application

Continuous waste plastic pyrolysis plant final product application

The final products produced in the continuous waste plastic pyrolysis plant have high economic values. The pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc, or as well as used for generators to get electricity. The carbon black can be used for making construction bricks and the steel wire(for waste tires) can be recycled into smelting plant.

Fuel oil application