WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

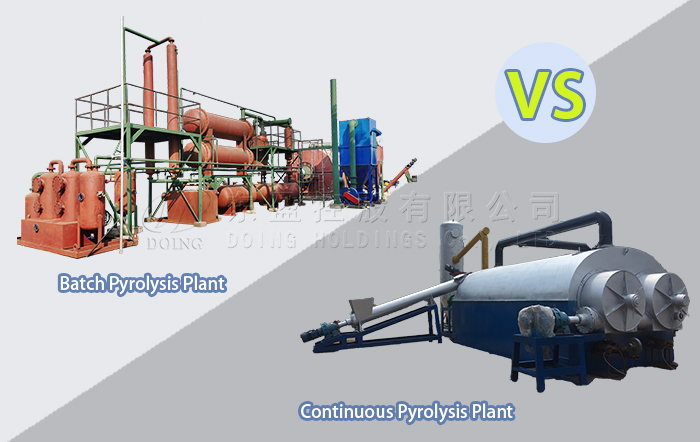

The waste tire to oil plant has been developed to this day, there have been many technological updates. Based on the current demand, our Doing company has developed continuous pyrolysis plant on the basis of batch pyrolysis plant. But they have different process lines and are different in many aspects, so what are the main differences between them? Let's take a look in detail.

Batch pyrolysis plant and continuous pyrolysis plant

Batch pyrolysis plant and continuous pyrolysis plant

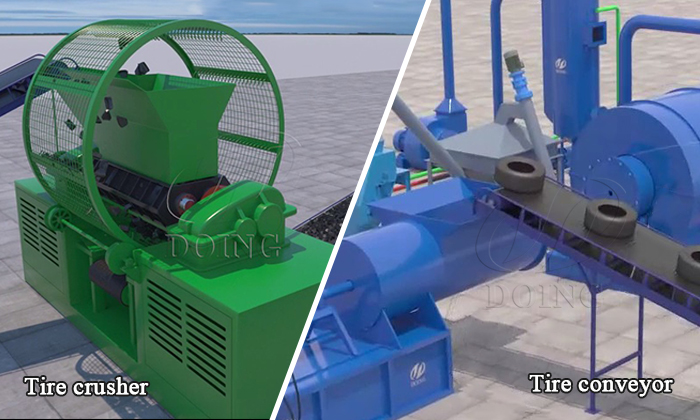

1.Different waste tire pretreatment

The batch pyrolysis plant directly feeds the tires into the reactor for processing, while the continuous pyrolysis plant needs to pre-treat the tires,first using a wire drawing machine to extract the steel wire from the tires, and then using rubber powder equipment to process it into rubber powder before feeding it to the reactor for pyrolysis.

Tire crusher and tire conveyor

Tire crusher and tire conveyor

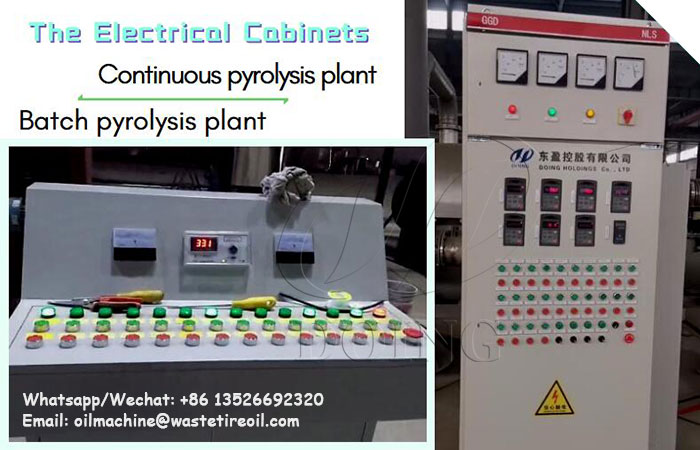

2.Different degrees of automation

The continuous pyrolysis plant adopts PLC control system, automatic feeding and automatic slag discharge, which can be continuously performed 24 hours a day,requiring only 1-2 workers. The batch pyrolysis plant requires 3-4 workers to assist in the operation, and the slag discharge has to wait until the reactor has cooled down before proceeding.

Automatic control system of tire pyrolysis plant

Automatic control system of tire pyrolysis plant

3.Different environmental protection levels

Both the environmental protection measures of the batch pyrolysis plant and the continuous pyrolysis plant have reached the national environmental protection requirement standard. Since the continuous pyrolysis plant seals the feeding and slagging process, effectively preventing pollution from contacting the atmosphere, and is safer and more environmentally friendly than the open feeding and discharging of batch pyrolysis plant.

4.Different processing capacity and oil yield

The continuous pyrolysis plant has a larger processing capacity. The processing capacity of the batch pyrolysis plant is 100 kg, 500 kg, 1 ton, 2 tons, 5 tons, 10 tons, 12 tons and 15 tons, while continuous pyrolysis plant can handle 15 tons, 20 tons, 30 Tons and 50 tons. You can choose anyone according to your needs. If you want to handle other quantities, we can also customize it for you. In terms of oil yield,continuous pyrolysis plant can fully react the waste tires during the pyrolysis process because of its finer feeding method and fully automatic operation, resulting in higher oil yield.

In general, continuous pyrolysis plants are more environmentally friendly, efficient, and intelligent, but the corresponding initial investment cost is also high. If you want a more detailed understanding of the difference between the two plants, you can contact us at any time, our professional salesman will help you analyze the most suitable equipment.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.