WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan DOING Environmental Protection Technology Co., Ltd specializes in manufacturing pyrolysis plants, offering three main types: batch type, semi-continuous type and fully continuous type. The semi-continuous type, positioned between batch type and fully continuous plants, boasts distinct advantages that make it an appealing choice for waste management and resource recovery. Here are the key advantages of DOING semi-continuous Pyrolysis Plants:

1. Enhanced Efficiency:

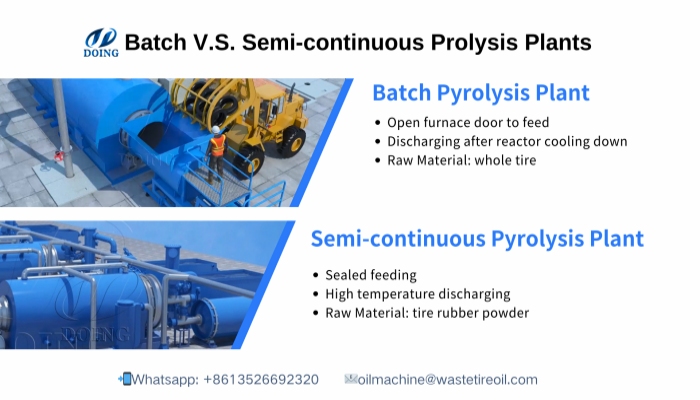

More Efficient Than Batch Plants: DOING semi-continuous plants achieve higher efficiency compared to Batch plants. It can complete three batches within two days and allow for direct discharge after pyrolysis, eliminating the need for saving reactor cooling times required in Batch systems (typically 4-5 hours).

Difference between batch type and semi-continuous pyrolysis plants

Difference between batch type and semi-continuous pyrolysis plants

2. Cost-Effectiveness:

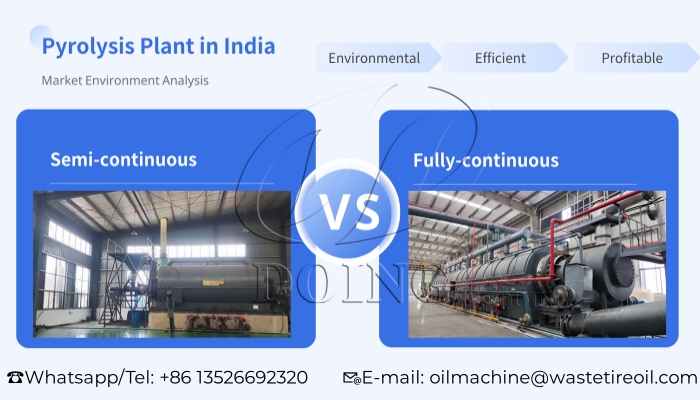

Cost Advantage Over Fully Continuous Plants: semi-continuous plants are priced slightly higher than batch plants but significantly lower than fully continuous ones. This affordability makes them a viable option for clients who find fully continuous plants too expensive initially.

Reduced Operational Costs: Since semi-continuous plants require the tire to be shredded into rubber powder before processing, there's no need to remove steel wire post-pyrolysis, reducing carbon black pollution in the workshop and cutting operational costs.

DOING semi-continuous and fully continuous pyrolysis plants

DOING semi-continuous and fully continuous pyrolysis plants

3. Versatile Processing:

Apart from the common waste tires and plastics, it can also handle high oil content oil sludge: DOING's specially designed semi-continuous plants can process oil sludge with up to 80% oil content efficiently. They can manage one batch per day with an anti-coking design tailored for high oil content materials.

4. Transitionary Solution:

Meeting Diverse Client Needs: The semi-continuous plant serves as a transitional solution, offering higher efficiency and environmental friendliness than Batch plants while being more affordable than Fully Continuous ones. This flexibility caters to clients who have higher requirements for the pyrolysis plants but are unable to invest in Fully Continuous ones initially.

DOING semi-continuous pyrolysis plant for sale

DOING semi-continuous pyrolysis plant for sale

In conclusion, semi-continuous pyrolysis plants have their unique advantages, becoming the best choice for solid waste management recycling. Here DOING can provide the semi-continuous pyrolysis plant with the processing capacity between 1 to 20 tons per day. If you want to invest in the recycling industry, welcome to contact us!

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.