WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

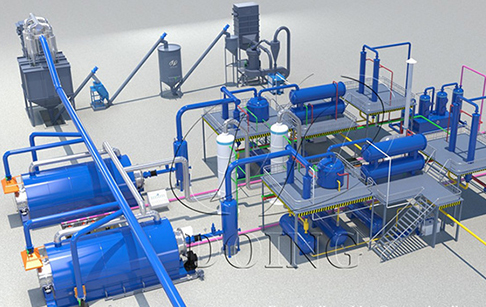

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

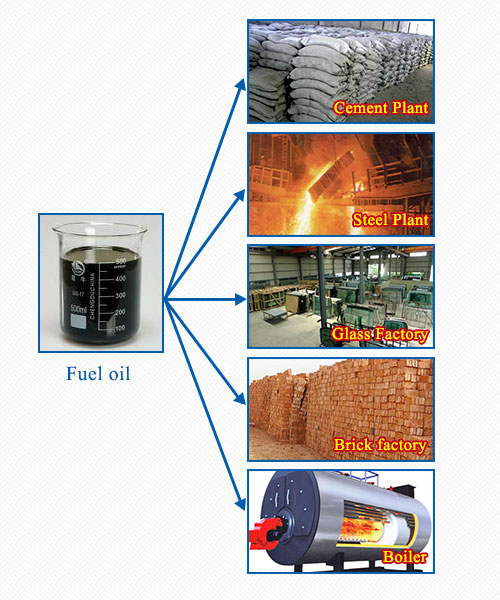

| NO | Name | Percentage | Usage |

| 1 | Tyre fuel oil | 45% |

1.Can be sold directly 2.Can be as fuel 3.Can be used industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic factory. |

| 2 | Carbon black | 30% |

1.Can be sold directly 2.Can be used electric cable jacketing,black nylon bag,rubber additive |

| 3 | Steel wire | 15% |

1.Can be sold directly 2.Make steel bloom by use hydraulic press-packing |

| 4 | Oil gas | 10% |

1.Can be as fuel burn by use gas burning system 2.Extra gas also be storage as fuel for other heating |

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

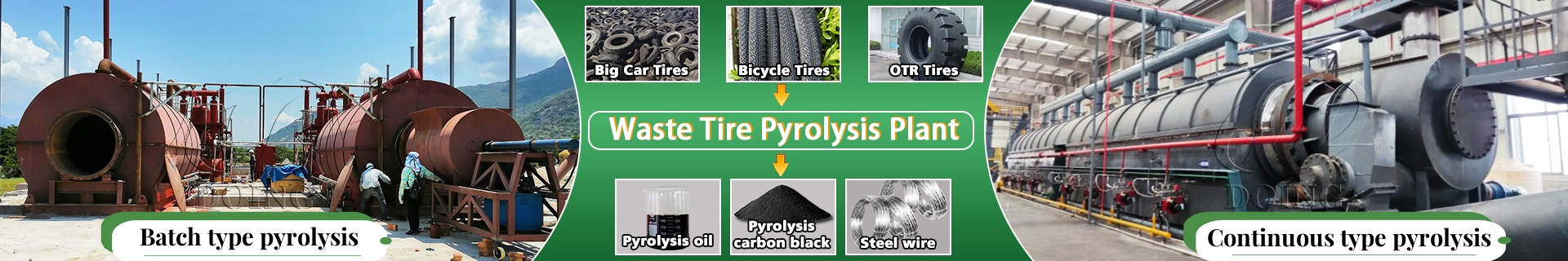

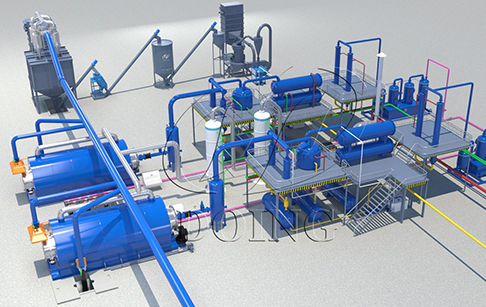

Skid-mounted waste tire plastic pyrolysis plant for sale

Skid-mounted waste tire plastic pyrolysis plant for sale

Waste Tyre Pyrolysis Machine Technical Parameters

Waste Tyre Pyrolysis Machine Technical Parameters

Waste tire to oil pyrolysis plant

Waste tire to oil pyrolysis plant

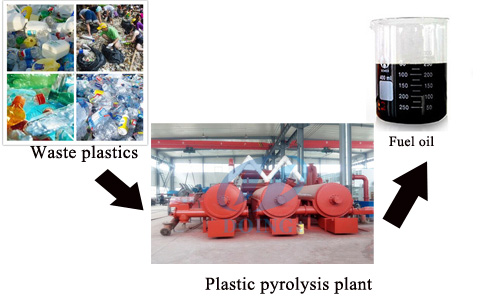

DOING Continuous Waste Plastic To Oil Machine

DOING Continuous Waste Plastic To Oil Machine

Oil sludge pyrolysis plant

Oil sludge pyrolysis plant

Small scale waste tyre pyrolysis equipment

Small scale waste tyre pyrolysis equipment

New design pyrolysis plant convert waste plastic to fuel oil

New design pyrolysis plant convert waste plastic to fuel oil

Waste tyre oil extraction and pyrolysis plant for sale

Waste tyre oil extraction and pyrolysis plant for sale

Waste tire recycling plant

Waste tire recycling plant

12T pyrolysis plant recycling waste tires to fuel oil

12T pyrolysis plant recycling waste tires to fuel oil