WhatsApp

WhatsApp

+86-135-2669-2320

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

| Technical parameter of waste tyre oil extraction pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Wastet yre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Waste tyre oil extraction pyrolysis plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

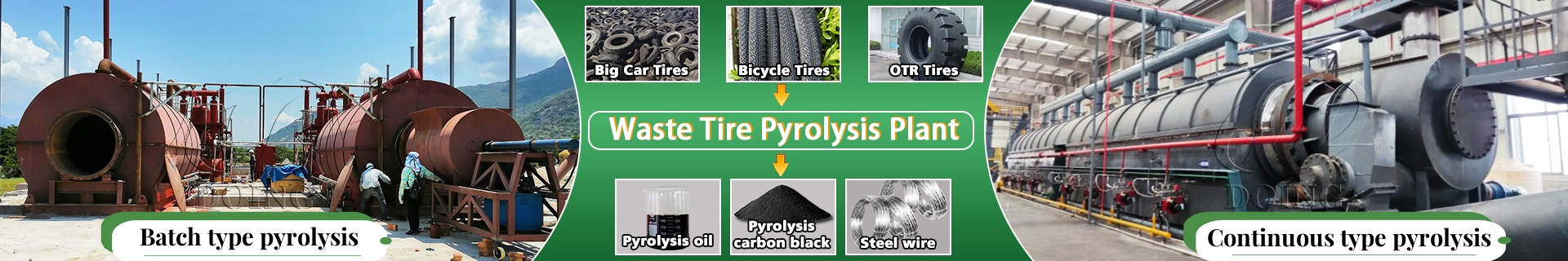

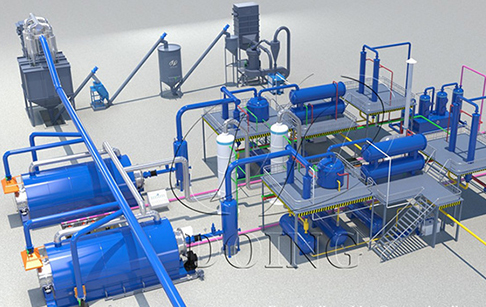

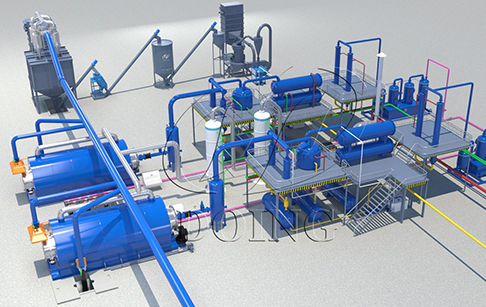

Skid-mounted waste tire plastic pyrolysis plant for sale

Skid-mounted waste tire plastic pyrolysis plant for sale

Waste Tyre Pyrolysis Machine Technical Parameters

Waste Tyre Pyrolysis Machine Technical Parameters

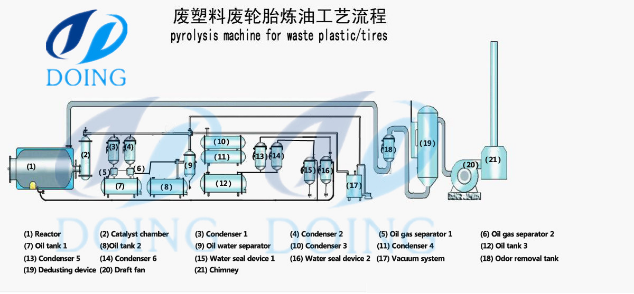

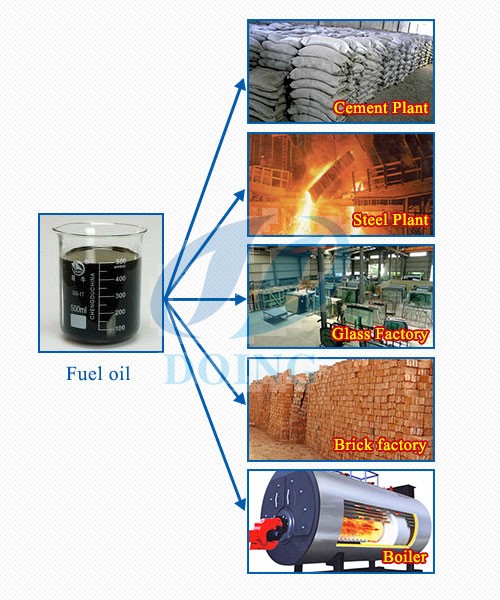

Waste tire to oil pyrolysis plant

Waste tire to oil pyrolysis plant

DOING Continuous Waste Plastic To Oil Machine

DOING Continuous Waste Plastic To Oil Machine

Oil sludge pyrolysis plant

Oil sludge pyrolysis plant

Small scale waste tyre pyrolysis equipment

Small scale waste tyre pyrolysis equipment

New design pyrolysis plant convert waste plastic to fuel oil

New design pyrolysis plant convert waste plastic to fuel oil

Waste tyre oil extraction and pyrolysis plant for sale

Waste tyre oil extraction and pyrolysis plant for sale

Waste tire recycling plant

Waste tire recycling plant

12T pyrolysis plant recycling waste tires to fuel oil

12T pyrolysis plant recycling waste tires to fuel oil