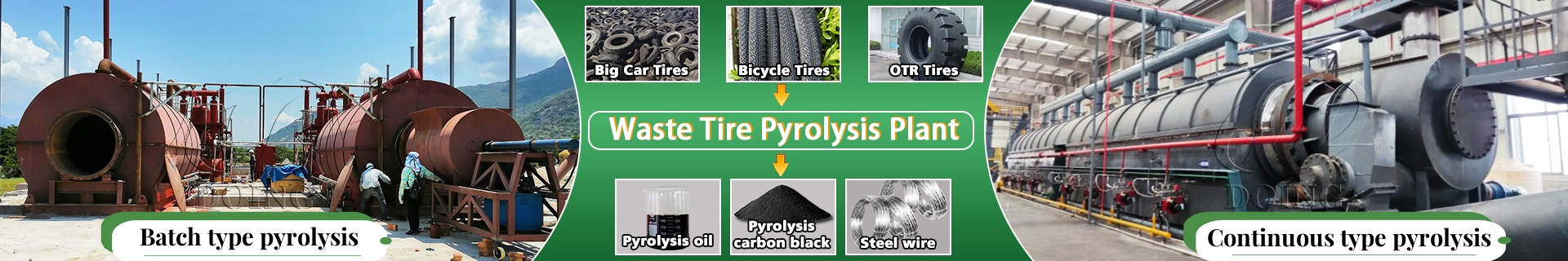

Waste tyre

How do the waste tyres influence people’s life so much? Nowadays, disused tyres disposal becomes a very current topic as many problems caused by tyres pile will explode sooner or later. The most noticeable problem associated with large tyre piles is the fire hazard they present. Once a tyre pile catches fire, it is very hard to extinguish. In some instances, tyre piles have been burning for several months with the black fumes being visible for many miles. Diseases such as encephalitis and dengue fever have also been reported around scrap tyre piles, particularly in areas with warmer climates which are an ideal breeding ground for disease-carrying mosquitoes. The waste tyre pyrolysis to oil machineoffered by Doing compnay can convert waste tyre to fuel oil ,carbon black and steel wire .

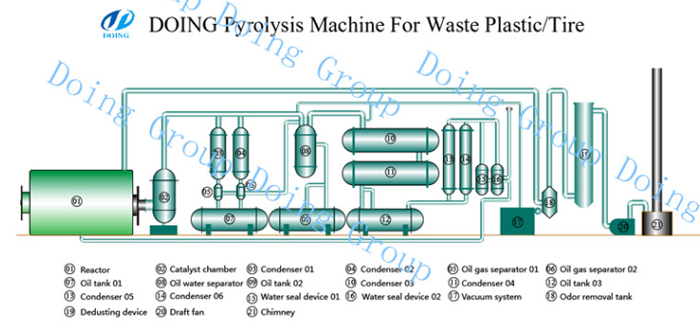

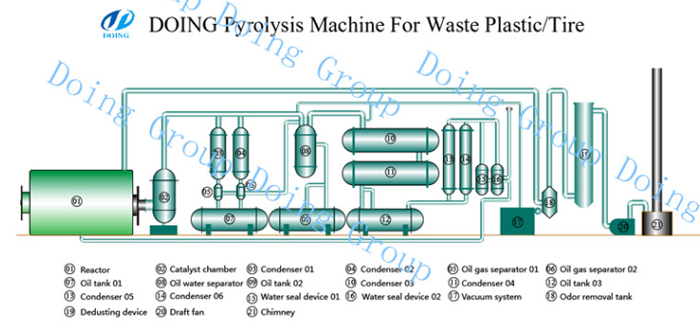

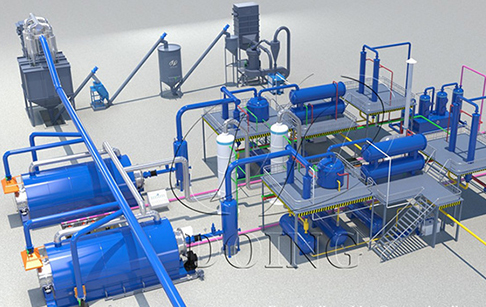

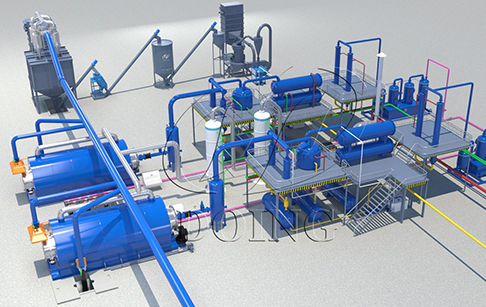

Waste tyre pyrolysis to oil machine

Waste tyre pyrolysis to oil machine working principle:

Waste tyre pyrolysis to oil machine working principle

1. Use auto-feeder to feed the waste tyres into reactor automatically, seal the feeding inlet door tightly.

2. Heat the reactor by burning the following fuel material: coal, wood, natural gas, or fuel oil in the combustion system. The reactor will be heated slowly, when the temperature reaches around 250 degree Celsius, the oil gas will be formed.

3. After processed by DOING waste tyre pyrolysis to oil machine, the oil gas will go to the cooling system to be liquefied. The gas which cannot be liquefied under normal pressure will be designed to go back to combustion system through safety device instead of the fuel material to burn the reactor, which is environmental friendly and can save you much energy.

4. After finishing oil collecting, the temperature of reactor will be down, while, carbon black can be discharged automatically at the same time.

5. When the temperature falls down to 100 degree Celsius, workers can open the door of reactor to discharge the steel wire.

6. Start another batch working.

We DOING Company as a leading company for manufacturing and supplying waste tyre pyrolysis to oil machine has specialized in this field for almost 10 years, 4 years for domestic market, 6 years for international trade.

Waste tyre pyrolysis to oil machine installed in different countries

By now, we have installed hundreds of machines in more than 30 countries all over the world:

Africa: Egypt, Nigeria, Sudan, Ethiopia, Congo, Uganda;

Europe: Romania, Poland, Italy, Macedonia, Albania, Turkey, Estonia;

Asia: Malaysia, Pakistan, India, Thailand, Iran, Bangladesh, Lebanon, Jordan, UAE;

America: Mexico, Ecuador, Haiti, Guatemala, Aruba, Panama, Jamaica, Colombia.

And we have very professional engineers which can sent to your site for machine installation, commissioning and training your workers.

waste tyre pyrolysis to oil machine technical data

|

Technical parameter of waste tyre pyrolysis to oil machine |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tyre |

Waste tyre |

Waste tyre |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about waste tyre pyrolysis to oil machine |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

DOING waste tyre pyrolysis to oil machine is a good investment for recycling company and energy organization. DOING GROUP pyrolysis machine with a high quality machine, experienced manufacturer and good service, you will never regret. If you have any interest, please contact us. We will serve for you anytime.

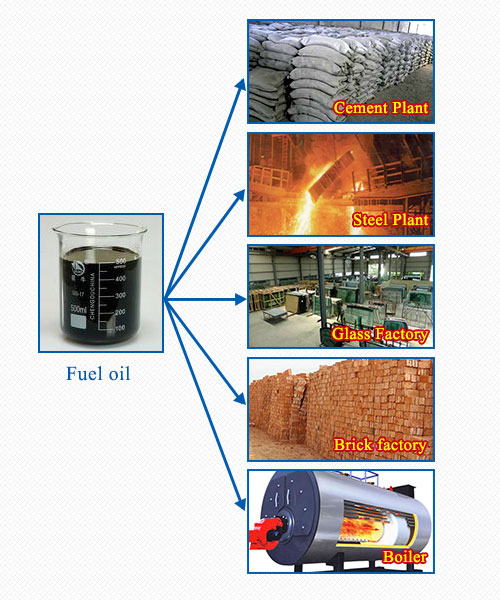

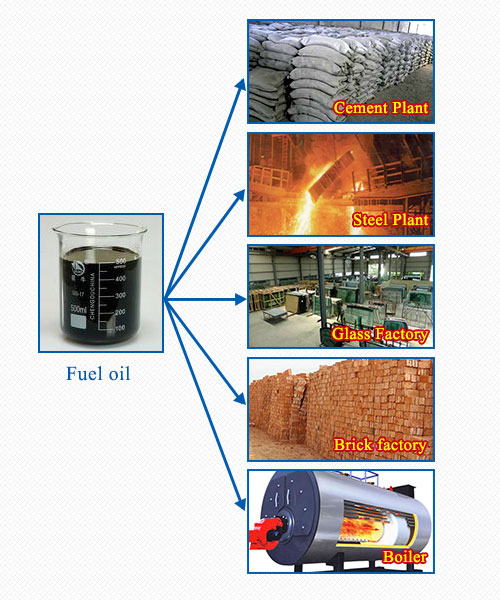

Final products and usage of waste tyre pyrolysis to oil machine:

1. Tyre oil 45%-55%

Fuel oil application

A. Sell directly. B. Turn to diesel and gasoline by oil distillation machine. C. Fuel materials.

2. Carbon black 30% -35%

Carbon black application

A. Sell directly. B. Reprocessing to fine carbon by carbon black refining machine.

3. Steel wire 10%-15%

A. Sell directly. B. Deep processing to steel bloom by hydraulic press-packing.

WhatsApp

WhatsApp

Skid-mounted waste tire plastic pyrolysis plant for sale

Skid-mounted waste tire plastic pyrolysis plant for sale

Waste Tyre Pyrolysis Machine Technical Parameters

Waste Tyre Pyrolysis Machine Technical Parameters

Waste tire to oil pyrolysis plant

Waste tire to oil pyrolysis plant

DOING Continuous Waste Plastic To Oil Machine

DOING Continuous Waste Plastic To Oil Machine

Oil sludge pyrolysis plant

Oil sludge pyrolysis plant

Small scale waste tyre pyrolysis equipment

Small scale waste tyre pyrolysis equipment

New design pyrolysis plant convert waste plastic to fuel oil

New design pyrolysis plant convert waste plastic to fuel oil

Waste tyre oil extraction and pyrolysis plant for sale

Waste tyre oil extraction and pyrolysis plant for sale

Waste tire recycling plant

Waste tire recycling plant

12T pyrolysis plant recycling waste tires to fuel oil

12T pyrolysis plant recycling waste tires to fuel oil