Waste tyre

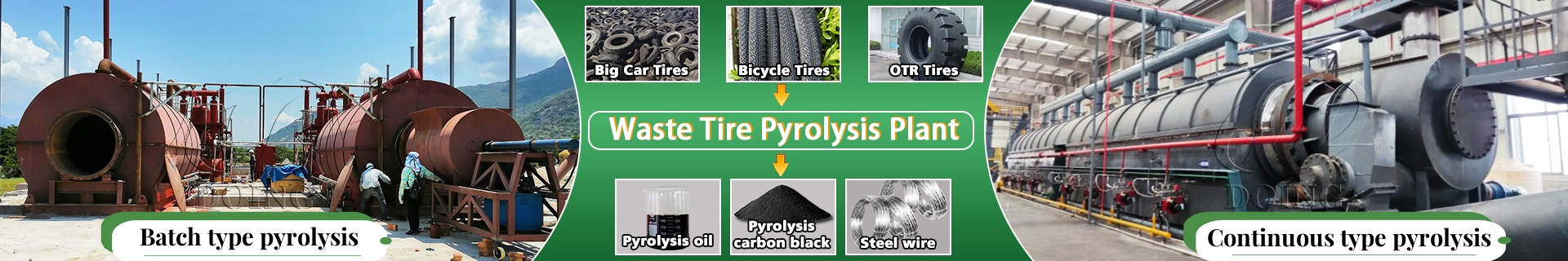

Cars have been a necessity in our daily life, and the more cars we use, the more waste tyres will produce. Thus how to deal with those waste tyres is a troublesome problem. Recycling those waste tire is a good idea, thus you can choose used tyre pyrolysis equipment.

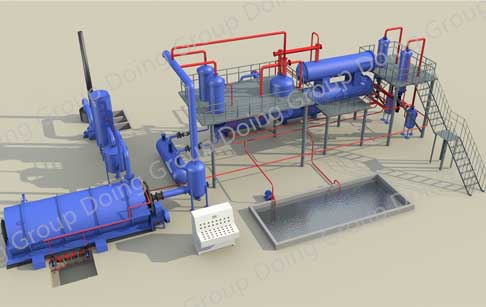

Small capacity used tyre pyrolysis equipment

Doing used tyre pyrolysis equipment is a new green technology to recycletyre and Doing have applied this technology in used tyre pyrolysis equipment. By using the used tyre pyrolysis equipment, finally you can get these pyrolysis products, such as fuel oil, carbon black and some combustible gas, all of which have a wide range of applications.

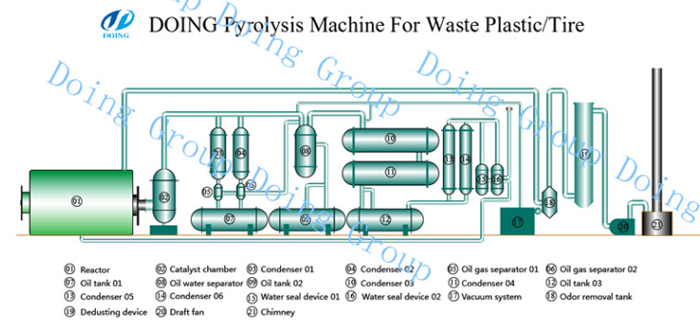

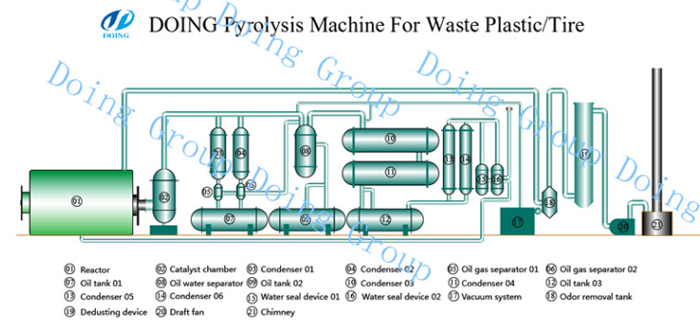

Small capacity used tyre pyrolysis equipment working process

Small capacity used tyre pyrolysis equipment working process

1.Feed raw materials

The raw material can be waste tire/waste plastic/waste rubber. Always feed by the auto feeder.

2.Pyrolysis

Include a reactor and catalyst room. Heat the reactor by coal/wood/oil/natural gas. This part will produce high temperature oil gas, the oil gas then flow into the next system.

3. Condensing

Oil gas come out from the reactor and catalyst chamber then cooling down in this part. Condensing system include condenser pipe, oil water separator, horizontal condenser and waste gas condenser. This will make the oil yield to the maximum.

4.Waste gas recovery

This part mainly deal with the gas that cannot be condensed. The whole process is very steady and high efficiency.

5. Discharge

After finished oil produce, the temperature of reactor can be cooled down, When the temperature falls down to 40 degree then carbon black can be discharged automatically by the way of anticlockwise rotate the reactor. The carbon black will drop into slag pool and then use screw conveyor to clean the slag pool. After discharging the carbon black, we can discharge the steel wire. There is steel wire hook in the auto-feeder, we only need put the steel wire hook into the reactor, and start the motor, the steel wire can be pulled out easily, there is no need for workers to contact the reactor, it is very convenient.

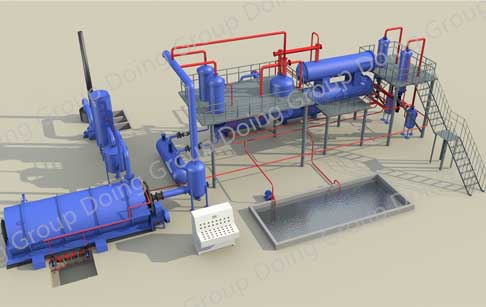

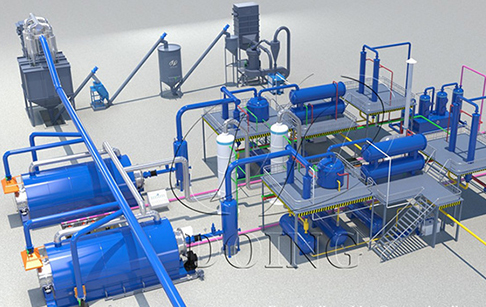

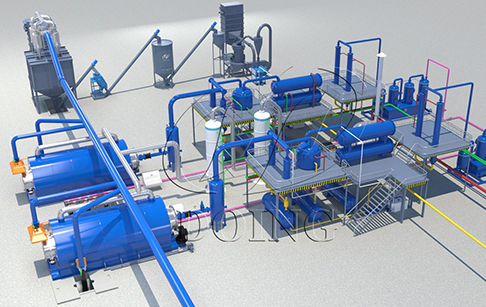

3 D picture of small capacity used tyre pyrolysis equipment

3 D picture of small capacity used tyre pyrolysis equipment

The small capacity used tyre pyrolysis equipment method is a technique which heats tyres in a sealed reactor. In the reactor the tyre is softened after which the tyre continuously into oil by cooling system.

The most important is machine reactor, DOING small capacity used tyre pyrolysis equipment reactor has some advantages as below:

1. The raw material of reactor is Q245R. Q245R is mainly used for pressure vessel because it can be continuously heated for long time. To keep a long service life.

2. Auto-welding with carbon arc air gouging technique.

3. The reactor is fully covered by thermal insulation. Heat preservation effect is good.

4. The gear is separated from the reactor. It avoids deformation after being heated for long time. Even it is broken you only need to change the gear. The maintenance cost is low.

5. There is a safety net inside the reactor. It prevents the raw materials going to accessories and avoiding blocking.

6. There are spiral plates inside of the reactor cab help to auto-feed and slag.

7. Feed port is round shape. It can work with auto-feeder. It helps you feed more raw materials and improve working efficiency.

Used tyre pyrolysis equipment technical data

|

Technical parameter of used tyre pyrolysis equipment |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tyre |

Waste tyre |

Waste tyre |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about used tyre pyrolysis equipment |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

Small capacity used tyre pyrolysis equipment final product application

Small capacity used tyre pyrolysis equipment is a good project for recycling centers, collection organizations etc. DOING used tyre pyrolysis equipment adhere to constantly updated product, guarantee high-quality product and offer full-service for our clients. DOING is your trustworthy partner, welcome to contact us.

Fuel oil application

Those final products have a wide range of applications. For the tyre pyrolysis oil, on the one hand, it can be sold directly or widely used as industrial fuel materials for burning. On the other hand, if further refined to diesel or gasoline, it can be directly used in low speed engines such as digging machine, road roller or loading machine, etc. The Carbon black can be used for construction bricks with clay, also can be used as fuel. The steel wire can be recycled into smelting plant.

WhatsApp

WhatsApp

Skid-mounted waste tire plastic pyrolysis plant for sale

Skid-mounted waste tire plastic pyrolysis plant for sale

Waste Tyre Pyrolysis Machine Technical Parameters

Waste Tyre Pyrolysis Machine Technical Parameters

Waste tire to oil pyrolysis plant

Waste tire to oil pyrolysis plant

DOING Continuous Waste Plastic To Oil Machine

DOING Continuous Waste Plastic To Oil Machine

Oil sludge pyrolysis plant

Oil sludge pyrolysis plant

Small scale waste tyre pyrolysis equipment

Small scale waste tyre pyrolysis equipment

New design pyrolysis plant convert waste plastic to fuel oil

New design pyrolysis plant convert waste plastic to fuel oil

Waste tyre oil extraction and pyrolysis plant for sale

Waste tyre oil extraction and pyrolysis plant for sale

Waste tire recycling plant

Waste tire recycling plant

12T pyrolysis plant recycling waste tires to fuel oil

12T pyrolysis plant recycling waste tires to fuel oil