WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Waste plasitc

Waste plasitc

Plastics have woven their way into our daily lives and now pose a tremendous threat to the environment. Over 100million tons of plastics are produced annually worldwide, and the common destination for used plastic is landfills. While efforts have been done to make biodegradable plastics, there have not been many conclusive measures towards cleaning up the existing problem. Here, the process of waste plastic to oil plant is explained as a viable solution for recycling plastics.

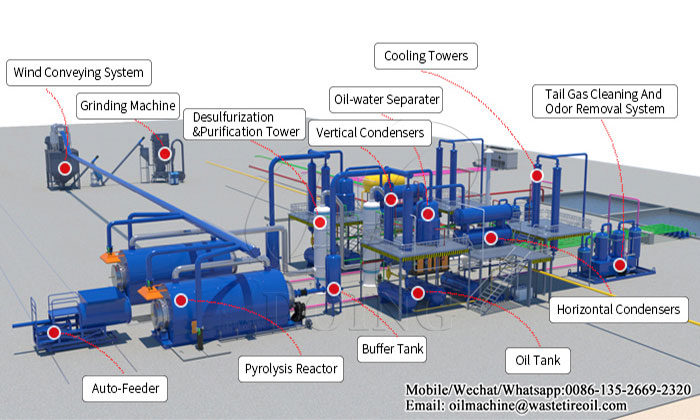

Waste plastic to oil plant

Waste plastic to oil plant

Doing waste plastic to oil plant with lower cost and higher fuel oil output can convert waste plastic to fuel oil and carbon black.

10t low price waste plastic to oil plant employs new green pyrolysis technology. It can not only pyrolyze plastic, but also recycle waste tires and waste rubber. After years of research and improvement, Doing group has achieved great success on the pyrolysis technology.

✔ 10t low price waste plastic to oil plant pyrolysis process:

10t low price waste plastic to oil plant pyrolysis process

10t low price waste plastic to oil plant pyrolysis process

The pyrolysis process is an advanced conversion technology that has the ability to produce a clean, high-calorific value fuel from a wide variety of biomass and waste streams. It is the thermo-chemical decomposition of organic material at elevated temperatures in the absence of oxygen. The pyrolysis provides various operational, environmental and economical advantages. Under pressure and heat, the long chain polymers of hydrogen, oxygen, and carbon decompose into short-chain petroleum hydrocarbons with a ceiling length of around 18 carbons. Hydrocarbon molecules from the basic materials are split under the impact of the catalytic (carbon material) convertor inside the reactor at 70–240 °C. The reduction of process temperature takes place from 500–600 °C to 240 °C. The higher yield of liquid fuel of about 98 % was achieved.

✔ 10t low price waste plastic to oil plant pyrolysis process advantage:

10t low price waste plastic to oil plant

10t low price waste plastic to oil plant

♣ Safety

We have some safe devices such as the pressure gauge, alarming ring, safety valve. at the same time we have the anti-back fire device which can avoid the fire back into the reactor.

♣ Environment protecting

If you come to visit our company to see the running plant, you cannot even see the vapor. as we have the dust removal device and dust removal pool.

♣ Energy saving

Our anti-back fire device can collect the exhaust gases which can be fuels after the oil is out so is very convenient and you can save the energy .at the same time, we have the catalyst chamber which can reduce the temperature of the catalytic prolysis of the tires and plastics. so you can save lot's of energy. except this ,we have vacuum device which let the reactor be negative pressure. So you can image.

♣ High degree of automatic

We have many automatically devices such as: auto-feeder, carbon black elevator, oil pumping automatic, reducing pressure automatic.

✔ Oil yield rate from waste plastic:

| PVC material | with very little oil, not good |

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

| Pure white plastic cloth | 70% |

| Plastic packag | 40% |

| Plastic logo | 20% |

| Paper coating | dry material 60%, wet 15%-20% |

| Household garbage | 30% - 50% |

| Pure plastic cable covers | 80% |

| Clean plastic bag more than 50% | 50% |

✔ Technical parameter of plastic to oil plant

| No. | Items | Contents | ||

| 1 | Equipmenttype | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Rawmaterial | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structuralform | Horizontalrotation | Horizontalrotation | Horizontalrotation |

| 4 | 24-hourCapacity | 6ton | 8ton | 10ton |

| 5 | Oilyield | 2.7-3.3ton | 3.6-4.4ton | 4.5-5.5ton |

| 6 | Operatingpressure | Normal | Normal | Normal |

| 7 | MaterialofpyrolysisReactor | Q245R | Q245R | Q245R |

| 8 | ThicknessofpyrolysisReactor | 16mm | 16mm | 16mm |

| 9 | RotatespeedofpyrolysisReactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Totalpower | 19KW | 19KW | 19KW |

| 11 | Modeofcooling | Watercooling | Watercooling | Watercooling |

| 12 | Coolingareaofcondenser | 100sqm | 100sqm | 100sqm |

| 13 | Kindoftransmission | Internalgeardrive | Internalgeardrive | Internalgeardrive |

| 14 | NoisedB(A) | ≤85 | ≤85 | ≤85 |

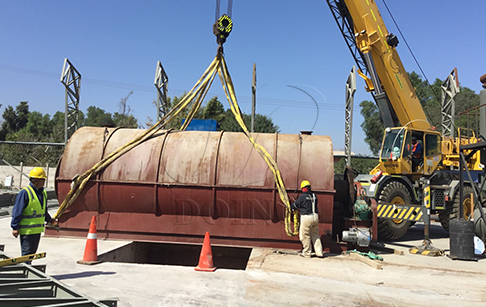

| 15 | SizeofReactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Workingform | Intermittentoperation | Intermittentoperation | Intermittentoperation |

| 17 | Deliverytime | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

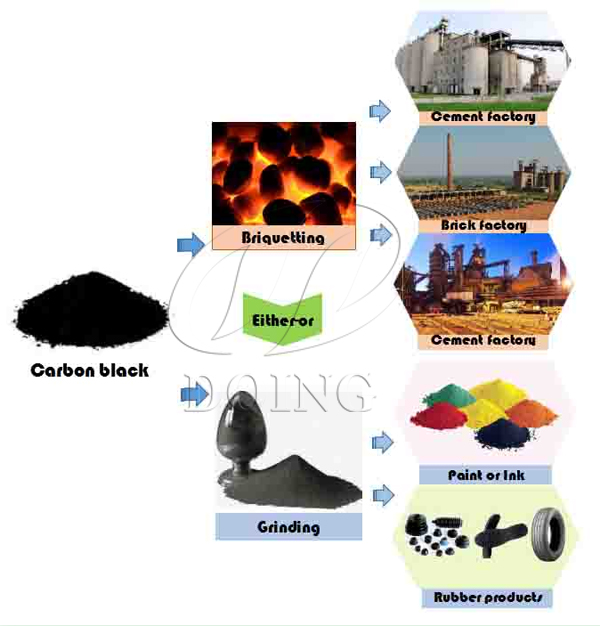

✔ Final product application genearaged by waste plastic to oil plant:

The final products of waste plastic to oil plant are mainly fuel oil and carbon black, and both of them have a wide range of applications in different fields.

• Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or chemical industries or hotels, restaurants etc. or used for generators to get electricity.

Fuel oil application

Fuel oil application

• Carbon black: Used for construction bricks with clay, also can be used as fuel.

Carbon black application

Carbon black application

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Small scale waste plastic pyrolysis plant

Small scale waste plastic pyrolysis plant

Waste Plastic to Fuel Machine

Waste Plastic to Fuel Machine

High oil rate waste plastic pyrolysis oil plant

High oil rate waste plastic pyrolysis oil plant

Automatic convert waste plastic to oil machine

Automatic convert waste plastic to oil machine

Hot sale waste plastic pyrolysis machine

Hot sale waste plastic pyrolysis machine

Waste plastic recycling to fuel oil plant

Waste plastic recycling to fuel oil plant

Advanced design waste plastic disposal machine

Advanced design waste plastic disposal machine

High capacity plant converts waste plastic to oil

High capacity plant converts waste plastic to oil

10t low price waste plastic to oil plant

10t low price waste plastic to oil plant

Convert plastic waste to fuel oil machine

Convert plastic waste to fuel oil machine