WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

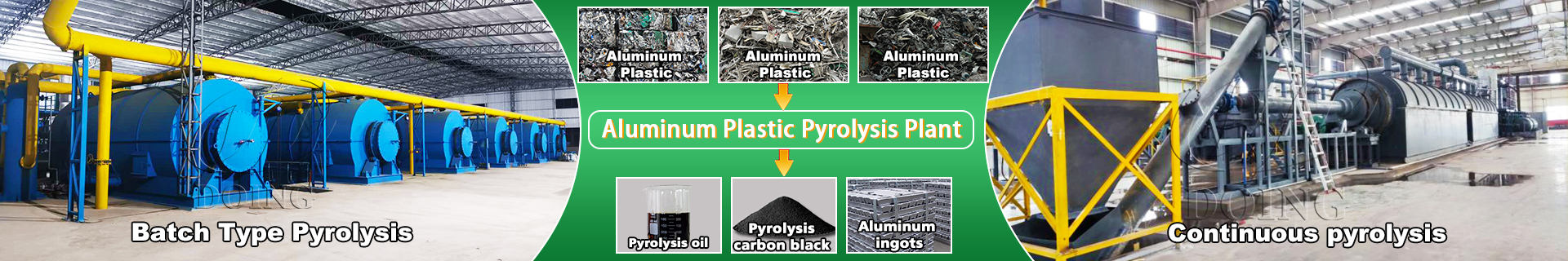

The aluminum and plastic pyrolysis machine uses the principle of pyrolysis to convert waste aluminum and plastic into fuel oil, combustible gas, aluminum slag and other energy sources in a high temperature and oxygen-free environment. In addition to core components such as reactors and condensers, the machine is also equipped with environmental protection and safety equipment such as exhaust gas purification system, desulfurization tower, water seal, vacuum device, etc.

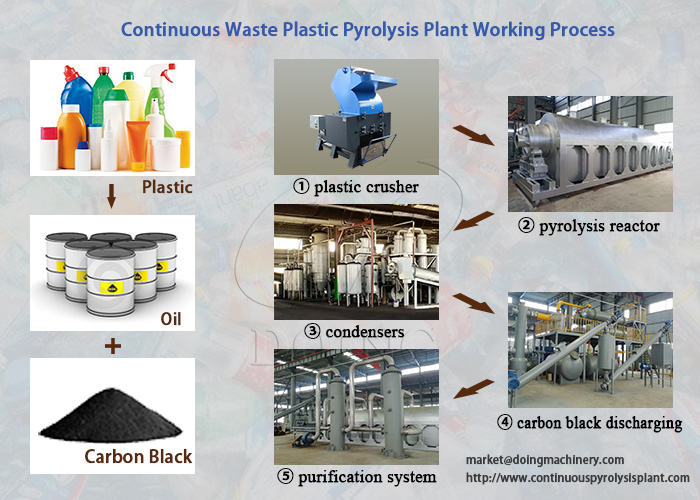

Aluminum and plastic pyrolysis machine working flow

Aluminum and plastic pyrolysis plant working flow

Aluminum and plastic pyrolysis plant working flow

1. Feed

Fully automatic continuous equipment is used to transport waste aluminum and plastics to the reactor, and the entire process is sealed to ensure safety and environmental protection.

2. High temperature pyrolysis

When the reactor is heated, the waste aluminum and plastics will be pyrolyzed under high temperature and oxygen-free conditions, oil and gas will be generated after reaching a certain temperature.

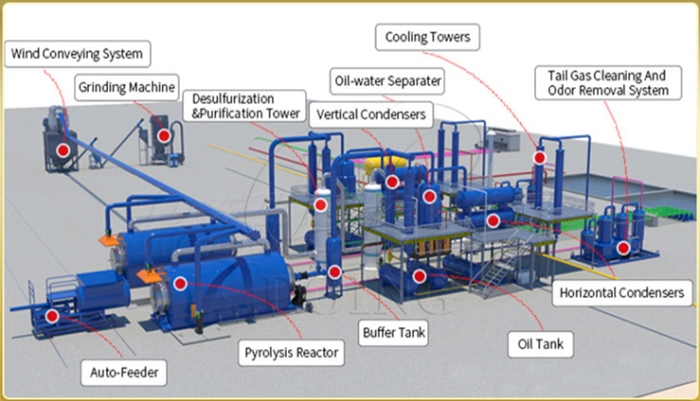

3. Cooling

The oil gas passes through the vertical condenser and the horizontal condenser in turn through the buffer of the buffer tank, then the oil gas is condensed into oil under the action of low temperature cooling.

4. Exhaust gas purification

After passing through the condensing system, the non-condensable oil and gas can be used as fuel to heat the reactor through the tail gas purification system.

5. Deslagging

After the oil and gas are exhausted, the continuous aluminum and plastic pyrolysis machine will automatically discharge the remaining aluminum and plastic slag in the furnace and collect it in a sealed manner.

6. Flue gas treatment

The flue gas generated during the heating process of the reactor enters the desulfurization tower for purification, it can be discharged into the atmosphere in accordance with the national environmental protection emission standard.

Products and applications of aluminum and plastic pyrolysis machine

Pyrolysis oil: it mainly used as industrial fuel and used in the production of steel plants, cement plants, power plants and other factories, and can also be further extracted from non-standard diesel or gasoline.

Aluminium slag: it sold to relevant manufacturers for re-smelting

Aluminum and plastic pyrolysis plant

Aluminum and plastic pyrolysis plant

Advantages of aluminum and plastic pyrolysis machine

1. Environmental protection

The waste aluminum and plastic pyrolysis machine is equipped with environmental protection devices. After the non-condensable combustible gas is processed by the tail gas purification system, it is used as fuel for the heating of the reactor. The flue gas generated during the heating process of the reactor enters the desulfurization tower for purification treatment, and reaches the national environmental protection emission standard. The entire process is well sealed to prevent dust pollution.

2. Security

The reactor adopts a standard arc-shaped pressure head design, which can bear high temperature and high pressure, one-piece pressing, and it is not easy to crack. The heat source does not directly contact the reactor and indirect heating makes the heating uniform and prolongs the service life of the reactor. The equipment is equipped with safety devices such as thermometers, pressure gauges and safety valves to ensure the operating conditions of the equipment at any time. In addition, it is equipped with water seals and vacuum devices to prevent the backflow of oil gas.

3. High oil yield

In the cooling stage, a vertical condenser and a horizontal condenser are set up in sequence. The most commonly used and most effective condenser in the pyrolysis industry is used to ensure that the pyrolysis oil gas is fully cooled and the oil output rate is high.

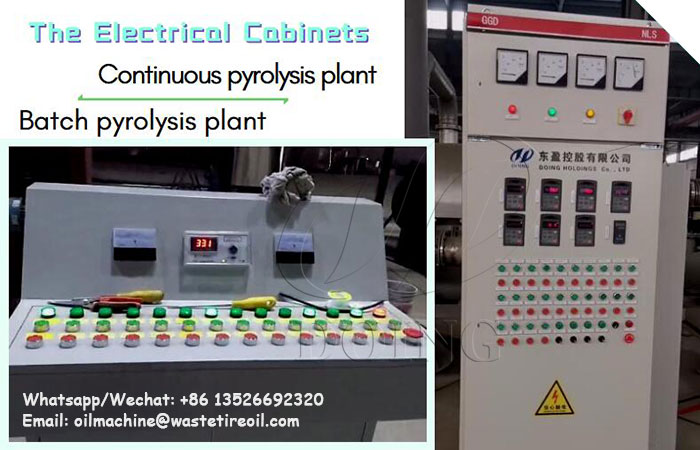

4. High degree of automation

PLC control system

PLC control system

Continuous waste aluminum and plastic pyrolysis machine adopts PLC control system, which is automatic feeding and slagging, so it saves time and effort, also saves fuel for preheating the reactor, and improves production efficiency.

Aluminum and plastic pyrolysis machine is a key factor in determining whether you are profitable, so choosing a good machine will do more with lewith less. Doing's waste aluminum and plastic pyrolysis machine has a high degree of automation, high oil yield, and can handle products of various scales. The quality has been recognized and trusted by more than 90 countries and regions around the world. Our factory has a complete set of complete and advanced prototype, welcome to visit and inspect at any time.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.