a.Simple operation, Fully automatic operation

b.Large quantity

c.Efficient Work

|

Item |

Briquetting machine |

Grinding mill |

Binder mixer |

conveyor |

|

1 |

|

|

|

|

|

2 |

YHQ-290 |

S112 |

Diameter:950mm |

Size : 5000 mm |

|

3 |

Deceleration model number: ZQ 350 type |

Every time mixing quantity: 100 kg |

Hight: 2700mm |

Quantity: 1 set |

|

4 |

Speed ratio: 1:31.5 |

Every time mixing time: 3-5 minutes |

Quantity: 1 set |

|

|

5 |

Roller size:φ290mm Width:200mm |

Productivity:

1.5-2ton/h |

|

|

|

6 |

Roll leather material: 65mn quenching process |

The total transmission ratio: 30.9 |

|

|

|

7 |

Surface hardness:56-58 |

Principal axis rotate:32r/min |

|

|

|

8 |

Spindle speed: 12-15 RPM |

Weight:1000kg |

|

|

|

9 |

Power: 5.5 kw |

Power: 4 kw |

|

|

|

10 |

Capacity:1.5-2 ton |

Speed: 1450 r/min |

|

|

|

11 |

Dimension:1600*1400*1400mm |

Quantity: 1 set |

|

|

|

12 |

Quantity: 1 set |

|

|

|

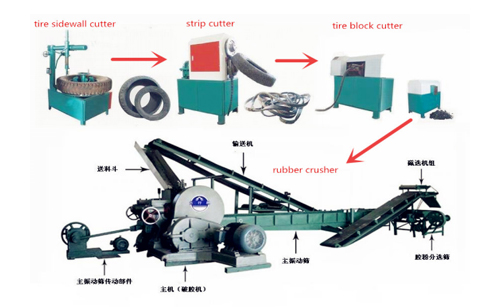

Carbon black pellet Production Line stirs in the Binder mixer with catalyst firstly, then put the stirred catalyst and carbon black into Grinding mill for stirring and mixing.The mixed carbon black is conveyed through the conveyor belt to the Carbon Black Briquetting machine,pressed into balls.

WhatsApp

WhatsApp