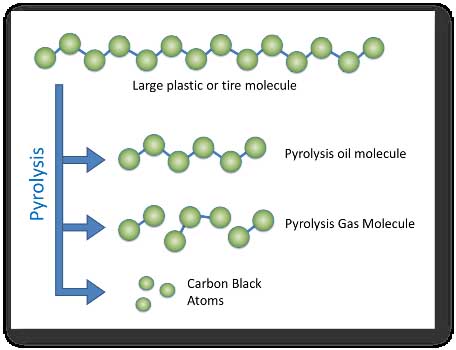

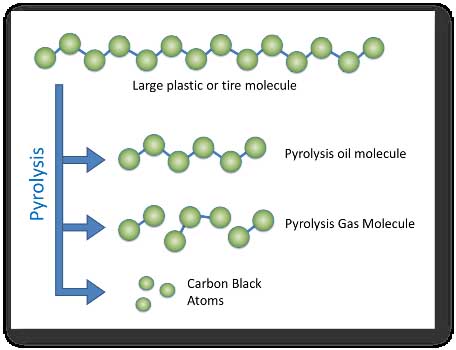

What is plastic and tire rubber Pyrolysis?

Plastic and tire rubber pyrolysis involves subjecting plastic and tire rubber to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic and tire rubber breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Like plastic and tire rubber , pyrolysis end products are also hydrocarbons. Pyrolysis is great way of recycling waste plastics and tires rubbers. Given below are benefits of waste plastic and tire rubber pyrolysis.

The benefit of plastic and tire rubber Pyrolysis:

Recycles synergy of waste plastic and tire rubber into usable fuel oil .

Offers renewable energy source.

The in product can be used as fuel in existing industrial boilers and furnaces. End products can also be used for generating electricity.

Eliminates hazard of land pollution by waste plastics and tire.

Converts waste into energy.

Clears dumping yards and environment of non bio degradable plastic and tire ubber waste.

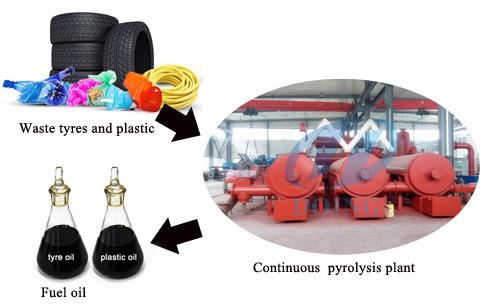

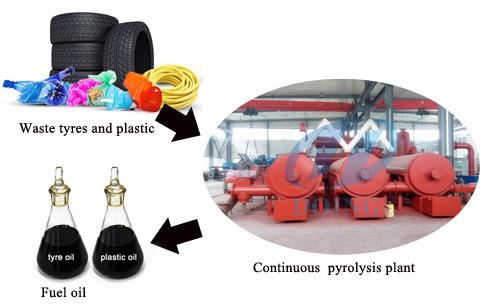

Continuous waste tire rubber plastics pyrolysis plant

Waste tire/rubber/platics pyrolysis is a thermo decomposition of tyre polymer, since waste tyres are long chain polymers containing more than 50,000 carbon atoms attached to each other in a cross linked or straight chain.

For continuous waste tire rubber plastics pyrolysis plant, its raw material can be waste tires, plastic and other rubber. If your raw material is waste tire, you can get fuel oil, carbon black and steel wire after pyrolysis processing. The following are the function of products from continuous waste tire rubber plastics pyrolysis plant.

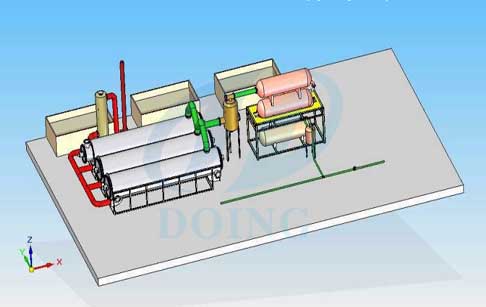

Continuous waste tire rubber plastics pyrolysis plant working process

1.The feedstock of Continuous waste tire rubber plastics pyrolysis plantis shredded tire/plastic/rubber chips with sizes less than 50 x 50mm. The feedstock is continuously fed into the reactor of Continuous waste tire rubber plastics pyrolysis plant through dedicated air-tight feeding device together with low-temperature sulfur transfer catalyst.

2. The vapor from waste tire/plastic/rubber pyrolysis will be mostly condensed into liquid fuel oil and a little amount of non-condensable combustible gas. The fuel oil will be stored for sales or further distillation.

Continuous waste tire rubber plastics pyrolysis plant

3. The non-condensable combustible gas will be scrubbed and burned in order to supply enough heat for Continuous waste tire rubber plastics pyrolysis plant. The exhaust gas will be mostly recycled to save energy and reduce operation cost and partially released after multiple purification process in compliance with local emission standard

4.The solid output includes crude carbon black and steel which will be separated by magnetic separator. The crude carbon black will be condensed and transferred through the enclosed conveying system to the carbon black production system for further processing into industrial carbon black or other value-added chemical materials. The separated steel will be sold at market price.

Continuous waste tire rubber plastics pyrolysis plant advantage

Continuous waste tire rubber plastics pyrolysis plant advantage

1. Safe: the operation is mainly operated through a high automation system and includes special devices, which include valve, thermometer, water seal, pressure value, oil water separator among other. Furthermore, the system includes strict testing devices from raw material that test the raw material at each and every step till the device production.

2. This process if environmentally friendly: the continual waste plastic recycling plant not merely recycles waste plastic, that any high environmental pollutant but also turn the waste to grease the industry marketable product.

3. Features high degree of automation: the complete process starting form feeding the waste plastic in to the system to discharging the carbon black is very controlled by PLC.

Continuous waste tire rubber plastics pyrolysis plant technical data

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

Output |

Fuel oil, carbon black |

Continuous waste tire rubber plastics pyrolysis plant application

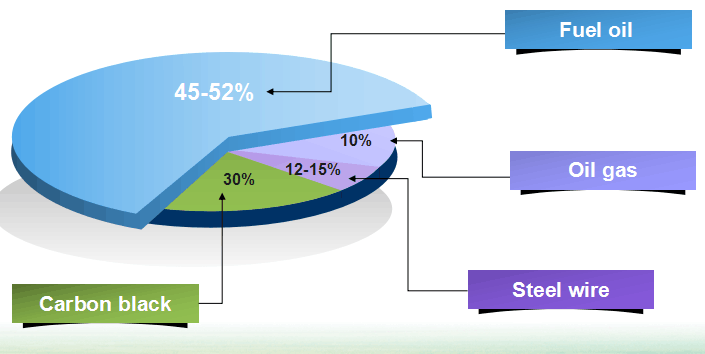

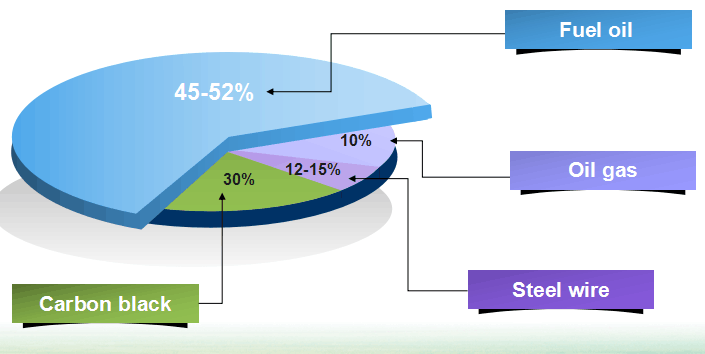

The percent of continuous waste tire rubber plastics pyrolysis plant

Fuel Oil (45% to 52%)

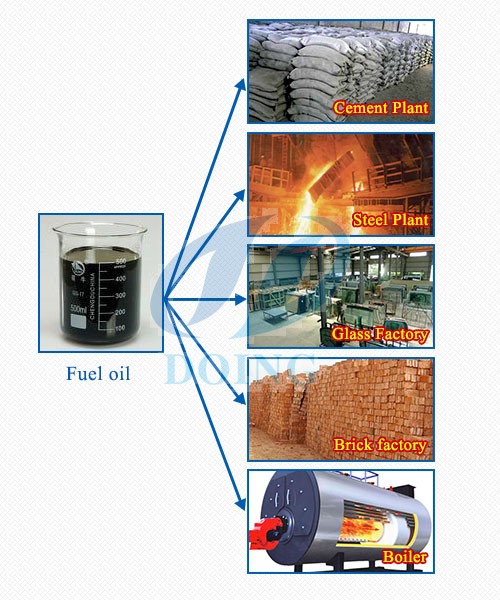

The main application of oil products produced by our continuous waste tire rubber plastics pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

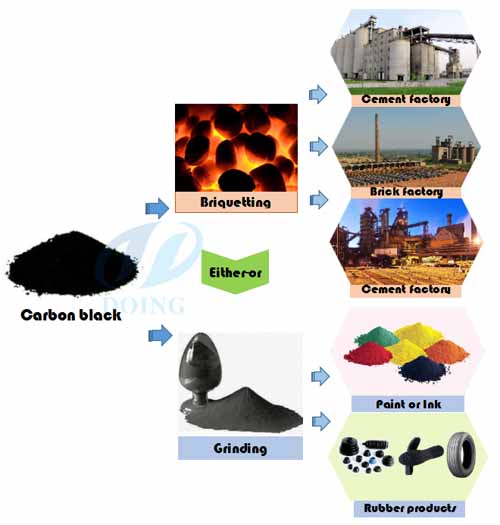

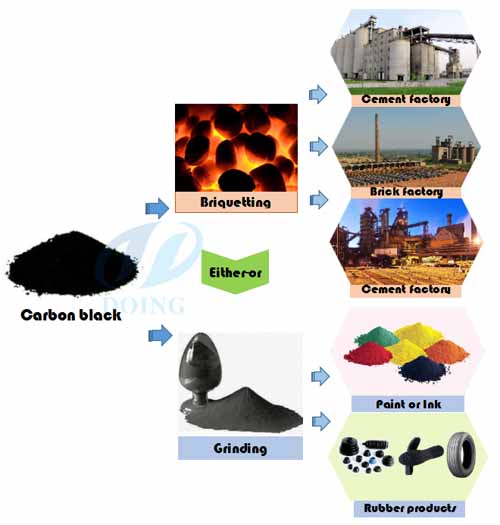

Carbon black application

Carbon black (30% )of continuous waste tire rubber plastic pyrolysis plant carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% of the total amount of scrap plastics recycled in the system.Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

Oil gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Steel Wire (12% to 15%)

The third product of continuous waste tire rubber plastics pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

WhatsApp

WhatsApp