WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

On one hand, with the moderation of the society, rubber industry is developing at a rapid speed, rubber products are widely used in many field of life, on the other hand, the pollutant of rubber, increasing for its difficulty in decomposing, which was called “Black Contamination”, has became a big threat to the environment and get increasingly serious. Compared to the developed countries, we are still lack of experiences in treating the pollution the capital and market are also big problems.

Waste tyre pyrolysis plant

Waste tyre pyrolysis plant

By using the waste tyre pyrolysis plant,we can get pyrolysis oil from waste tire. Secondly,with the help of one set of tire oil to diesel refining machine, the pyrolysis oil can be further refined into diesel oil or gasoline.

Tire oil to diesel refining machine

Tire oil to diesel refining machine

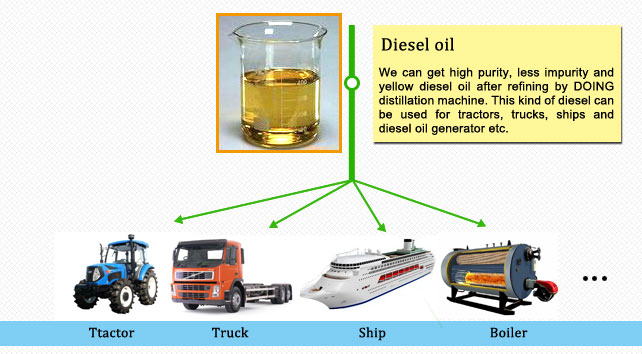

Tire oil to diesel refining machine can turn waste tyre oil to high quality diesel. This machine not only applied to tyre oil, also can use for plastic oil and waste engine oil. the final oil-diesel can be used for tractors, trucks, ships and generator power etc.

Tire oil to diesel refining machine advantages

1: To minimize the process of heating

By using the heat transfer heating system, our client can save much fuel to heat the whole reactor, and the heating speed is faster and the temperature can keep the reactor hot for longer time,so the whole process is faster with less fuel

2: The heating circulation system is more environmental

All the heat transfer system is a circulating system, the heat transfer oil is recycling inside the reactor. So in total, you can fire less fuel, which not only save your cost on fuel also it is more environmental-friendly. All the system is sealed, in the terms of smoke and smell, our new design Used oil refining plant workers better.

3:The vertical reactor

From our design,It is very easy to clean the slag , it will be down through the bottom of the vertical reactors. So the operation is easier

4: Continuously working

When operating the machine,first you pump oil inside the reactor to heat,after finishing heating,it will becoming oil gas and goes to cooling system,then go to another tank.So,the first reactor is empty,no need to stop,you could pump another tank of oil again into the first tank ,continuously working.

The advantages of DOING tire oil to diesel refining machine

The advantages of DOING tire oil to diesel refining machine

If you want to buy tire oil to diesel refining machine, below information should be know:

• 100% waste tyre oil recovery is achieved (no churn left after the process)

• During and after the process; no soil, water or air pollution is observed.

• The most cost-effective waste tyre oil refining to diesel technology in the world.

• Raw material (waste tyre) is cheap and easy to provide. These are the by-products of tyre production.

• The process can be applied to plastic oil and waste engine oil.

• Vertical structure form, easy for cleaning and maintenance.

• The system creates an alternative source of energy to replace petroleum products and natural gas.

• System gives the opportunity to governments and local administrations to deal with the waste tyre problem to a great extent.

• System prevents the spread of diseases caused by waste tires oil.

• We deliver plants with capacities of 5 ton to 50t/day and its multiples.

• The process of distillation has duration of 15 to 18 hours, depending on the quality of waste oil. Also it can work day and night. No need to stop.

DOING tire oil to diesel refining machine in customer's factory in Malaysia

DOING tire oil to diesel refining machine in customer's factory in Malaysia

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Diesel oil application

Diesel oil application

DOING tire oil to diesel refining machine can be used by waste engine oil recycler, waste oil collect center and people who have lots of waste tyres and plastic.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Engine oil purification machine

Engine oil purification machine

Advanced Waste Oil Distillation Plant for Sale

Advanced Waste Oil Distillation Plant for Sale

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Plastic to diesel process plant

Plastic to diesel process plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Tyre Pyrolysis Oil to Diesel Distillation Plant

Used lube oil refining plant for sale

Used lube oil refining plant for sale

Diesel oil made from crude oil working process

Diesel oil made from crude oil working process

Waste plastic to diesel process machine

Waste plastic to diesel process machine

Plastic to diesel converter plant

Plastic to diesel converter plant

Waste plastic to diesel and gasoline plant

Waste plastic to diesel and gasoline plant