WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

Henan Doing Environmental Protection Technology Co., Ltd

Leading Waste to Fuel Machine Manufacturer, Supplier & Exporter

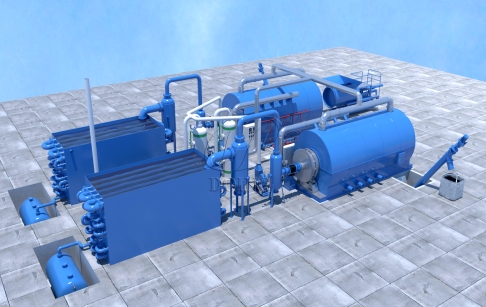

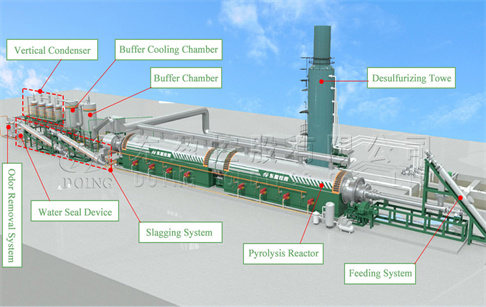

Semi-continuous tyre pyrolysis plant for sale is a kind of waste to energy plant developed and newly launched by Henan Doing Company. It adopts green processing technology, which offers innovative waste tyre recycling solution and can bring great economical and environmental benefits.

Process flow of semi-continuous tyre pyrolysis plant

1. Sealed feeding

Feed the rubber powder into pyrolysis reactor through the sealing sealed screw conveyor, which can complete the feeding operation of the reactor without opening the furnace door.

Noted: Batch type pyrolysis plant uses manual or hydraulic feeder to feed the whole tyres; while the semi-continuous type tyre pyrolysis plant requires to pretreate waste tyres into 16-18mm rubber powder.

2. Preheat the reactor

After the feeding is completed, turn on the burner to gradually heat the pyrolysis reactor, and at the same time rotate the pyrolysis reactor to ensure uniform and rapid heating. It usually takes about 2-3 hours for preheating reactor.

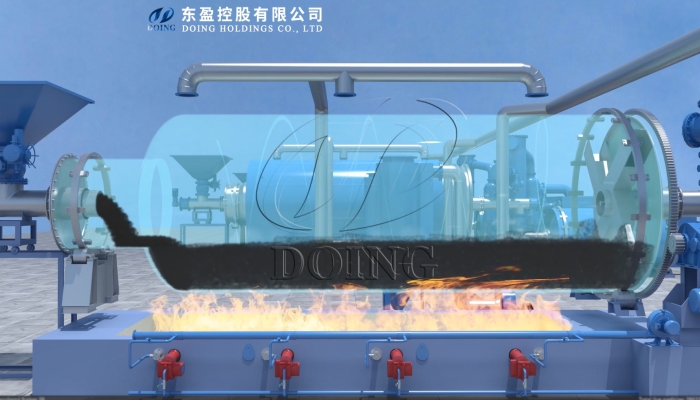

3. Pyrolysis

Under the condition of high temperature, the rubber powder undergoes pyrolysis and gasification reaction in the reactor. When the temperature reaches 280-320°C, a large amount of oil gas will be precipitated, and the oil gas will enter the condensation system for cooling into fuel oil.

Semi-continuous tyre pyrolysis plant reactor 3D picture

Semi-continuous tyre pyrolysis plant reactor 3D picture

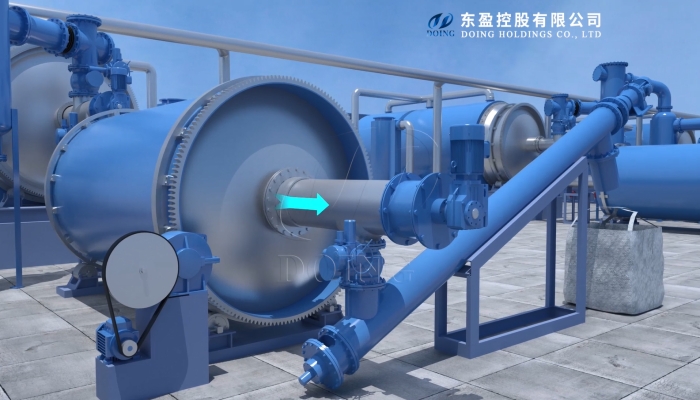

4. High temperature slag discharge

After the oil gas are fully pyrolyzed, the carbon black in the reactor is discharged into the small pyrolysis reactor for cooling and discharging; then we can start the next pyrolysis process.

The semi-continuous tyre pyrolysis plant can realize high-temperature slag discharge, which can improve production efficiency while saving energy and reducing consumption.

Semi-continuous tyre pyrolysis plant carbon black discharge system

Semi-continuous tyre pyrolysis plant carbon black discharge system

5. Condensation into oil

Oil gas come out from the gas outlet of the semi-continuous pyrolysis plant reactor and first pass through the buffer tank, the mud blocking tank, and then the water tank condenser/tube condenser to cool into oil and store in the oil tank.

6. Exhausted gas and flue gas purification

The remaining non-condensable combustible gas contains harmful gases such as hydrogen sulfide. After being purified by the desulfurization and deodorization system, it can be recycled and used to heat the reactor to save its own fuel. The flue gas generated in the pyrolysis plant reactor heating process can be directly discharged after the desulfurization and denitrification treatment.

Semi-continuous tyre pyrolysis plant environmental protection device

Semi-continuous tyre pyrolysis plant environmental protection device

Features of semi-continuous tyre pyrolysis plant

1. High temperature, airtight, automatic slag discharge: Clean and dust-free, save time, and can realize semi-continuous production operation.

2. Safety and environmental protection, stable operating conditions: Adopts sealed feeding and slag discharge, and is equipped with flue gas purification devices, exhaust gas purification devices and carbon black air transport systems simultaneously, no leakage, no dust, clean and environmentally friendly, and stable operating conditions of the equipment .

3. Large single-machine processing capacity and small footprint: The daily processing capacity of a semi-continuous tyre pyrolysis plant reaches 12 tons, 15 tons, 18 tons and 20 tons, with large processing capacity and high production capacity. And the equipment covers an area of about 450-600 square meters. Multiple reactors can be connected in series according to the customer's processing capacity, saving investment costs

Technical parameters of semi-continuous tyre pyrolysis plant for sale

| Item | Details |

| Available raw materials | Wastetyres, waste rubber, medical waste, municipal solid waste, coal tar, oil sludge |

| Final products | Pyrolysis oil, carbon black, steel wire, combustible gas |

| Model capacity | DY-C-12T, DY-C-15T, DY-C-18T, DY-C-20T |

| Reactor material | Q345R/Q245R boiler plate + 3045/316 stainless steel |

| Thickness | 14mm/16mm/18mm |

| Heating fuel | Direct heating by fuel oil, gas, coal, wood, etc. |

| Cooling type | Circulating water cooling |

| Floor area | Takes 20-ton machine as an example, 450-600 square meters |

Applications of the final product of semi-continuous tyre pyrolysis plant

1. Pyrolysis oil

It can directly replace fuel oil for industrial or boiler heating, such as cement plants, steel plants, glass plants, brick plants, heavy oil generators, HFO(heavy fuel oil) power plant, etc.;

It can be refined into diesel by waste oil distillation plant and used as light fuel for diesel generators, combustion engines, heavy machinery and agricultural machinery, such as tractors and ships.

2. Carbon black

It can be used for industrial heating by briquette combustion, and its combustion calorific value is equivalent to that of coal, which can directly replace coal;

It can be finely milled to make semi-reinforcing carbon blacks such as N550, N660, and N774, which can be used as additives for pigments and rubber products.

Semi-continuous tyre pyrolysis plant final products and applications

Semi-continuous tyre pyrolysis plant final products and applications

3. Steel wire

Sell it directly to the steel factory for smelting or waste recycling. The semi-continuous tyre pyrolysis plant draws out the steel wire in advance before pyrolysis, what is produced is a shiny and thin steel wire. Therefore, its appearance and quality are very good, and the market price is also high.

4. Combustible gas

After the combustible gas passes through the exhaust gas purification system, it can return to the reactor as fuel for heating and recycling.

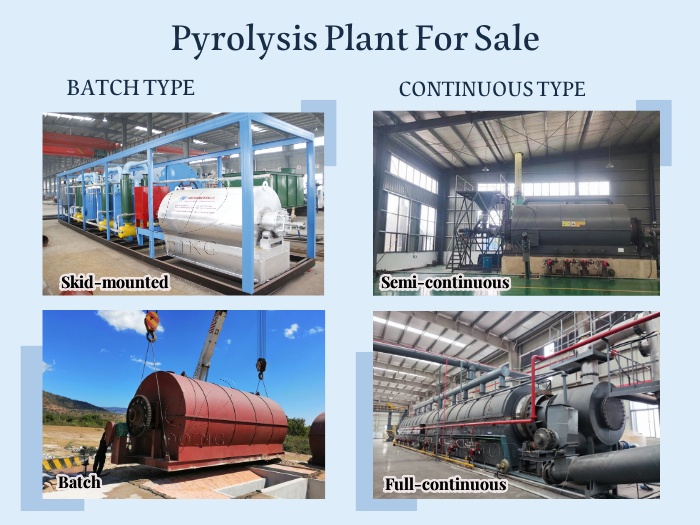

Different types of pyrolysis plants for sale

Different types of pyrolysis plants for sale

Henan Doing Environmental Protection Technology Co., Ltd. is deeply involved in the R&D and manufacturing of waste tyres/plastics/aluminum plastics/sludge/coal tar pyrolysis plant, and has established an equipment processing plant of about 40,000 square meters dedicated to equipment R&D, testing and fabrication. After technology iteration and upgrading, DOING pyrolysis plant has been continuously updated and upgraded. We have frame skid-mounted type, batch type, semi-continuous type and fully continuous type pyrolysis plant for sale, and there are complete specifications and models for you to choose from.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

Semi-continuous tyre pyrolysis plant for sale

Semi-continuous tyre pyrolysis plant for sale

Continuous model waste tyre pyrolysis plant

Continuous model waste tyre pyrolysis plant

Fully automatic continuous waste tire to oil plant

Fully automatic continuous waste tire to oil plant

Continuous automatic recycling tyre oil plant

Continuous automatic recycling tyre oil plant

Continuous fully automatic waste tyre pyrolysis plant

Continuous fully automatic waste tyre pyrolysis plant

Fully automatic continuous waste plastic pyrolysis plant

Fully automatic continuous waste plastic pyrolysis plant

New technology continuous waste tyre pyrolysis plant

New technology continuous waste tyre pyrolysis plant

Waste plastic continuous pyrolysis plants

Waste plastic continuous pyrolysis plants

Automatic and continuous waste tire plastic pyrolysis plant

Automatic and continuous waste tire plastic pyrolysis plant

No pollution fully automatic waste tyre pyrolysis plant

No pollution fully automatic waste tyre pyrolysis plant