Features

Waste tire

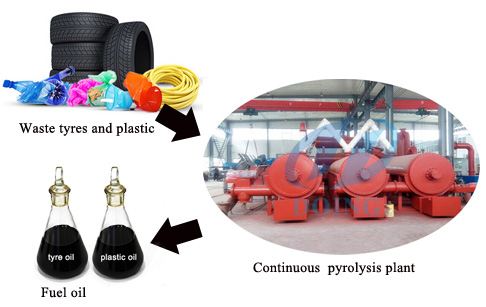

With the development of society, our daily life is full of rubber products, such as tyre, shoes and so on. On one hand, they make our life convenient, on the other hand, if not be treated directly, continuous pyrolysis tire to fuel oil supplier, it devoted to meeting the demands of all the customers.

Continuous pyrolysis tire to fuel recycling plant

For continuous pyrolysis tire to fuel recycling plant main raw material is waste tire/tyre.which can be easily available in and part of the world.

The raw material is cheaper and can use waste tire ,we get out put from waste as fuel oil,carbon black ,steel wire.

Continuous pyrolysis tire to fuel recycling plant is feasible in technology with small amount of invement,high availability of materials, short recovery period and with bright future, is the ideal choice of ininvesting.

Continuous pyrolysis tire to fuel recycling plant has perfect cooling system which is improved based on the old technology. It can ensure all the oil gas get cooled and converted into fuel oil.

Continuous pyrolysis tire to fuel recycling plant can process raw material and the oil yield

Continuous pyrolysis tire to fuel recycling plant

PP: Such as some thin films, plastic ropes, plastic crockery, plastic basin and barrel, furniture, woven bag, bottle cap, vehicle bumpers, etc. The oil yield is 90%.

PS: Such as some electrical appliance, stationery, cup, food container, household appliances shells, electric accessories, foam products, toys, etc. The oil yield is 90%.

ABS (Engineering plastics): about 40%

Pure white plastic cloth: about 70%

Bags of instant noodles: about 20%

Paper-mill waste: wet 15-20%, dry 60%

House hold garbage: 30-50%

Pure plastic cable skin: 80%

Pure clean plastic bags: more than 50%

General Rubbers:

Big truck tires: 45%

Small car tire and bike tire: about 35%

Rubber electric cable and shoe sole: about 35%

Mixture shoe sole: about 30%

Sport shoes: 20%-30%

Waste chemical fiber carpet: more than 30%

PMMA: 40%

Technical Data

Continuous pyrolysis tire to fuel technical data

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

Output |

Fuel oil, carbon black |

Application

Final product of application of continuous pyrolysis tire to fuel

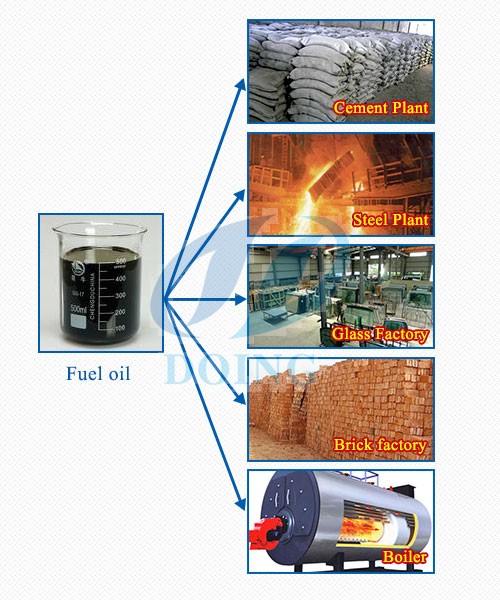

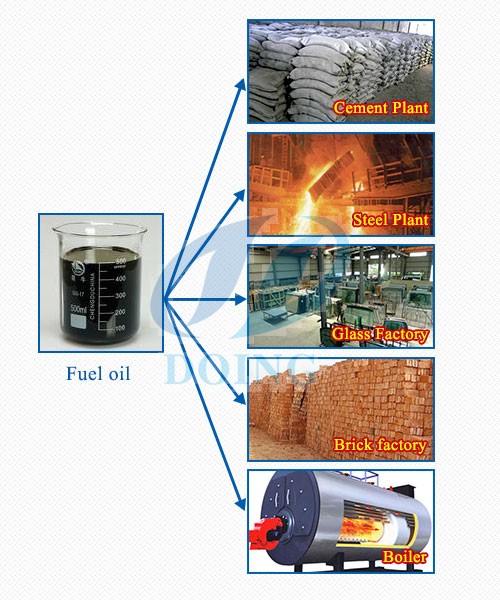

Fuel oil application

The main application of oil products produced by our continuous pyrolysis tire to fuel is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

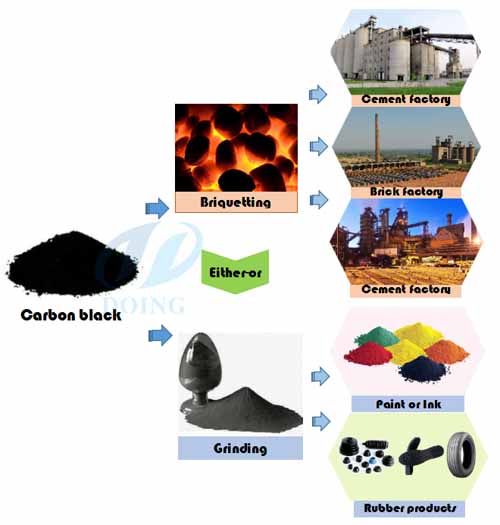

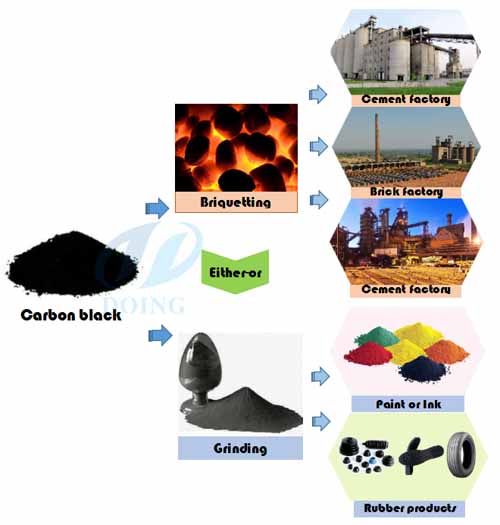

Carbon Black

Carbon black application

The second product of continuous pyrolysis tire to fuel is carbon black. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive